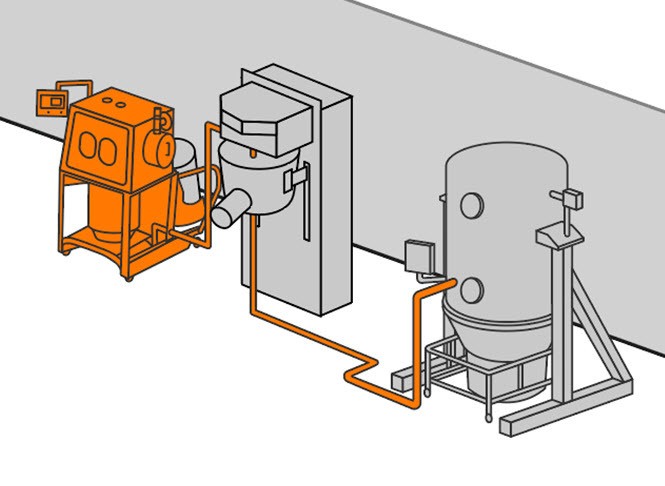

The solids loading process for high shear granulators and the transfer and unloading of the fluid bed dryer can be complicated. The potency of the powder, volume of materials, intermediate container type, potential risks of deflagration when solvents are present and maintaining sufficient uptime on Wet Granulation Suite are all key considerations that influence the determination of the best fitting solution. Rheo offers many solutions for handling a wide range of powders in your wet granulation process.

Wet Granulation (D)

1-0.01μg/m³

Containment

<1%

Oxygen Concentration in Vessel

3-5 minutes per drum

Cycle Time

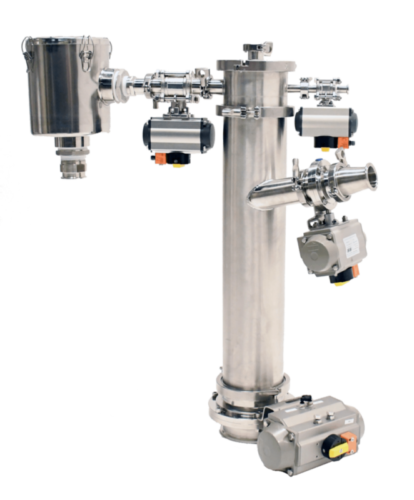

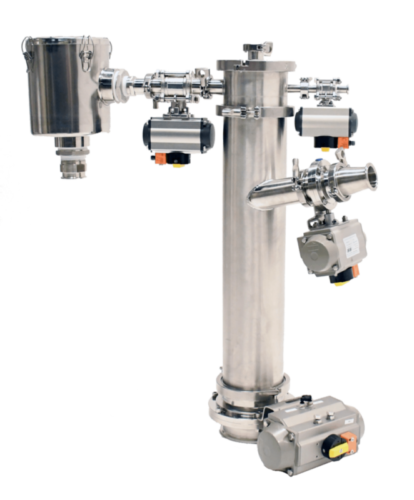

Material Transfer Station

The Rheo Material Transfer Station is designed to help operators transfer material out of drums using a small footprint workstation. Safety, containment, and productivity are all addressed with this simple to use machine.

Safety: Position drums directly across from the operator to optimize ergonomics. For potentially explosive products, the isolator can be flooded with nitrogen throughout the material handling process.

Containment: Material is transferred in a completely closed system to achieve containment levels of <1 µg/m³.

Productivity: Position drums directly above the receiving container for an easy transfer of powders. Cleanup time is minimized by using single-use glovebags or a CIP system for a rigid glovebox.

Vacuum Conveyance System (Supporting Product)

The Rheo Vacuum Conveyance System [VCS] provides a safe, efficient, and contained means for transferring material using a vacuum source instead of relying on gravity. The VCS is ideal for transferring highly toxic or potentially explosive powders that are present in the pharmaceutical, food, and chemical industries. Safety, containment, and productivity are all addressed with this simple to use machine.

Air Filtration Unit (Supporting Product)

Rheo offers a complete line of portable and stationary Air Filtration Units that provide a local HEPA filtration device to serve Local Exhaust Ventilation (LEV) systems. The Rheo Air Filtration Unit is designed to meet the utility requirements of multiple Rheo Ventilation Sleeves; it is also a good fit for any application with similar extraction utility requirements.

Each system is configured to comply with international electrical standards. The GMP compliant design features a small footprint and noise rating of 76 dBa. Safe Change filters and activated carbon filters for VOC’s are also available.

Rheo Air Filtration Units are a cost effective alternative to upgrading house exhaust systems that have become over utilized or where there is a need to prevent the contamination of the house exhaust system ducting.

Drum Mover (Supporting Product)

Rheo Drum Movers are designed to engage with drums of all types (fiber, plastic, and steel). The Drum Mover allows for the lifting and transportation of heavy drums anywhere within a manufacturing facility. There are various attachments that can be easily interchanged on the Drum Mover. The Chime Gripper design has a clamp that uses the drum weight to securely tighten against the drum chime. The Side Gripper design uses grippers that close securely on the drum before lifting. For effortless push-pull motions, a battery powered wheel drive can be integrated for complete powder handling.

Wet Granulation (A)

Wet Granulation (A) Wet Granulation (B)

Wet Granulation (B) Wet Granulation (C)

Wet Granulation (C)