The final stage of many API manufacturing processes is a powder sizing or milling process. This can process can utilize a wide variety of sizing equipment. The milling process is sometimes integrated into the packout process during the final drying stage, but often this is an stand-alone process. Common challenges with this process are associated with the handling of the dry powders. The transfer and milling process can be very dusty and may require inerting depending on the properties of the powder.

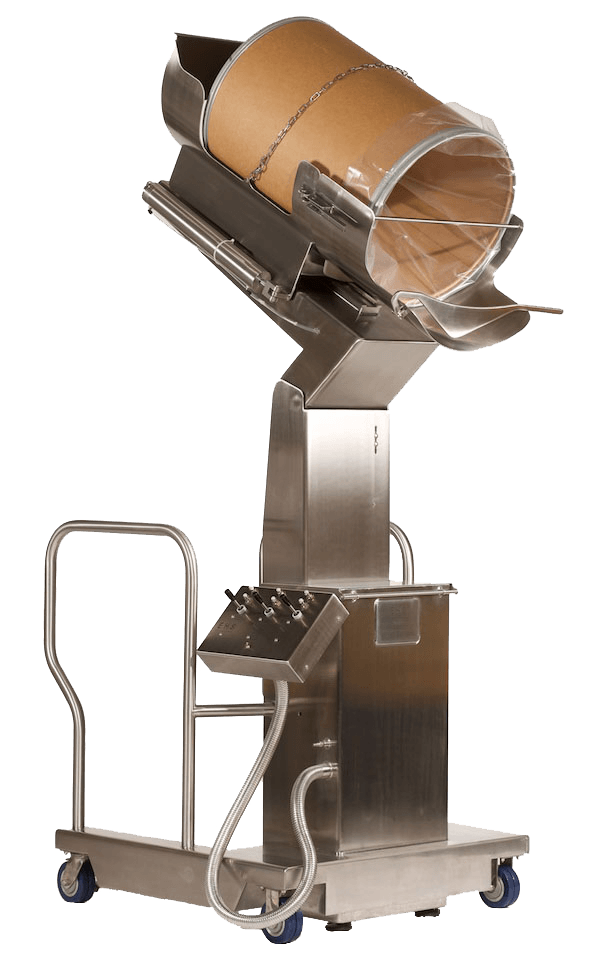

Rheo offers a drum handling and dust control system that allows the operator to safely transfer powder into the mill feed-chute as well as collect the milled powdered into a contained receiving drum.

Milling & Packout (B)

Milling & Packout (B)