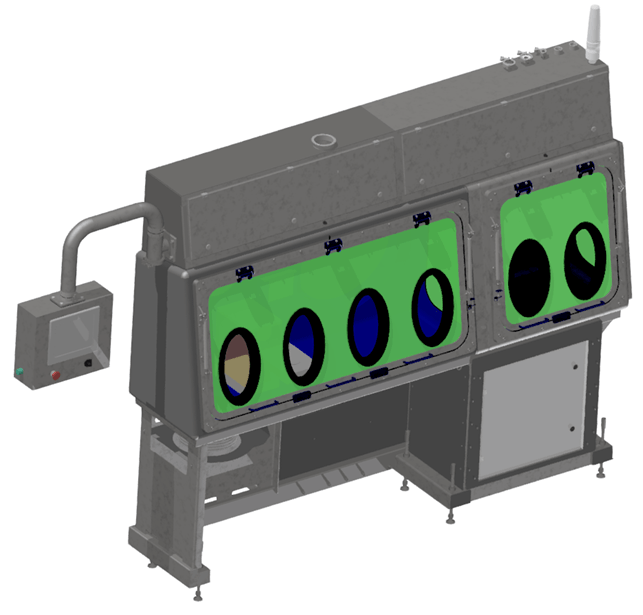

For this project, Rheo designed and built a hard-wall containment isolator for use during a weigh and dispense process. The isolator was equipped with a two-glove airlock chamber and a four-glove main chamber. The main chamber was equipped with a dispensing drum port as well as a Continuous Liner bag out port, both using RheoFlexibles canister design for contained entry and exit of materials. The isolator was equipped with an Allen Bradley touch screen HMI and automated pressure and oxygen % setpoints. An integrated exhaust blower with HEPA filter system ensured that the isolator was at a safe negative pressure throughout the dispensing process. Drums were loaded into the isolator via a GMP stainless steel Drum Tipper that was integrated into the isolator frame, for repeatable placement of drums into the drum port. The main chamber of the isolator was also equipped with power connections for client scales as well as mounts on the back wall of the isolator for the scale readouts.