Product sizing and milling is a frequent process in the manufacturing process. This often requires drum be emptied into the infeed chute of the mill, and then the powder is collected in a receiving drum. This process is labor intensive and can create high levels of airborne dust, often exceeding protection factor of operator PPE. Rheo has many options to improve both the safety and speed of this process. By integrating an inline mill into our Drum Inverter system, a handling step can be removed from the process. A mobile ventilation Sleeve can be used to provide local dust extraction at the screener discharge. This package dramatically improves the operator experience and reduces airborne dust during this process. This system also reduces cleaning time and cross contamination as it prevents dust from migrating throughout the process suite.

Dry Granulation (E)

100-10μg/m³

Containment

500cfm

Point Source Capture

Mobile Slewing Drum Inverter

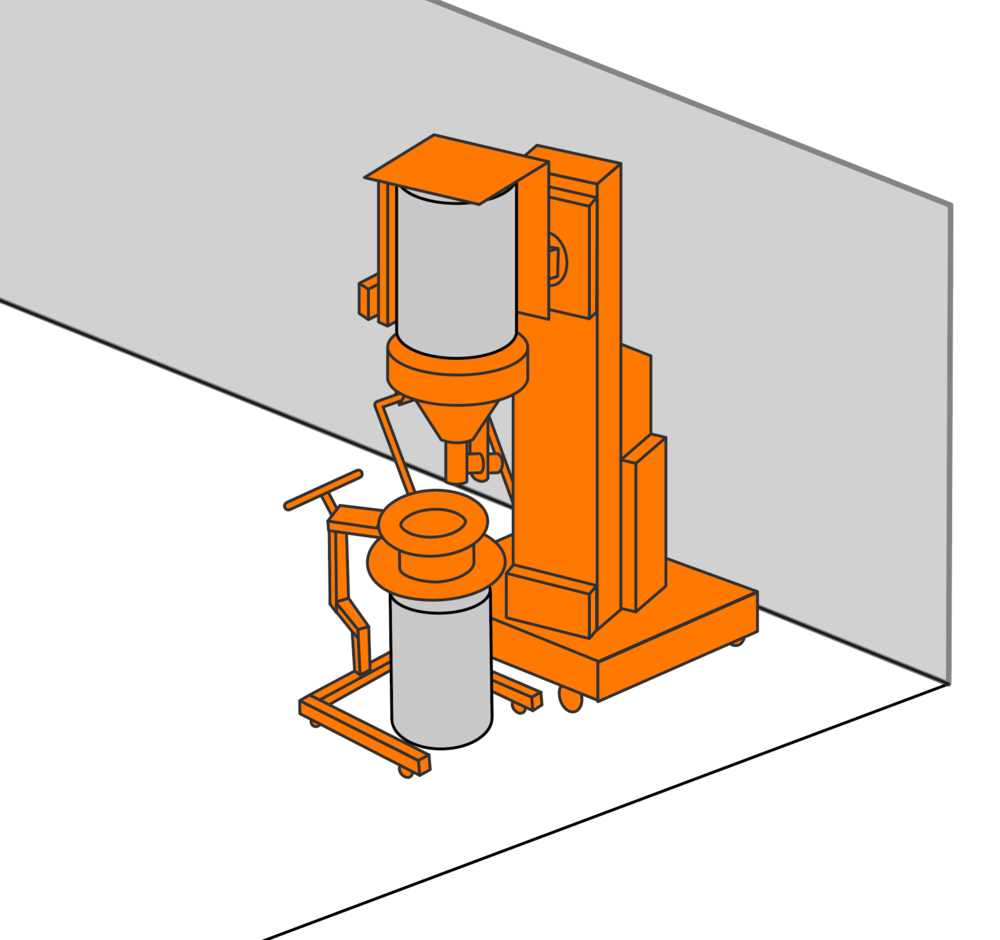

The Rheo Drum Inverter features a very robust and portable design that allows operators to lift and position drums above tall applications. Custom options on the Drum Inverter allow it to accommodate a wide variety of applications. A variety of compression cone designs are available to allow the Drum Inverter to be used with a range of drum diameters. The optional empty assist feature addresses the issues associated with powders trapped in the folds of the drum liner during inversion.

The column on this Mobile Slewing Drum Inverter rotates via a slewing bearing, allowing the operator to load a drum in one position and then rotate the machine into position over the discharge point. This allows the Drum Inverter to remain in the same position throughout the charging of multiple drums.

This design features an integrated Flexsift screener at the discharge of the compression cone.

Mobile Ventilation Sleeve

The Rheo Ventilation Sleeve provides localized dust extraction to capture airborne dust and vapor. The full perimeter slot design provides 360 degrees of extraction to ensure that the required capture velocity is achieved across the entire opening of the Ventilation Sleeve. Each Ventilation Sleeve is engineered to interface with the equipment it serves.

The Rheo Mobile Ventilation Sleeve allows the Rheo Ventilation Sleeve to be portable and utilizes a simple linkage design that makes the height adjustable.

The integrated transport cart allows the Ventilation Sleeve to be easily moved from one location to another. A lift-assist mechanism attaches the Ventilation Sleeve to the transport cart, allowing the height of the Ventilation Sleeve to be adjusted.

Air Filtration Unit (Supporting Product)

Rheo offers a complete line of portable and stationary Air Filtration Units that provide a local HEPA filtration device to serve Local Exhaust Ventilation (LEV) systems. The Rheo Air Filtration Unit is designed to meet the utility requirements of multiple Rheo Ventilation Sleeves; it is also a good fit for any application with similar extraction utility requirements.

Each system is configured to comply with international electrical standards. The GMP compliant design features a small footprint and noise rating of 76 dBa. Safe Change filters and activated carbon filters for VOC’s are also available.

Rheo Air Filtration Units are a cost effective alternative to upgrading house exhaust systems that have become over utilized or where there is a need to prevent the contamination of the house exhaust system ducting.