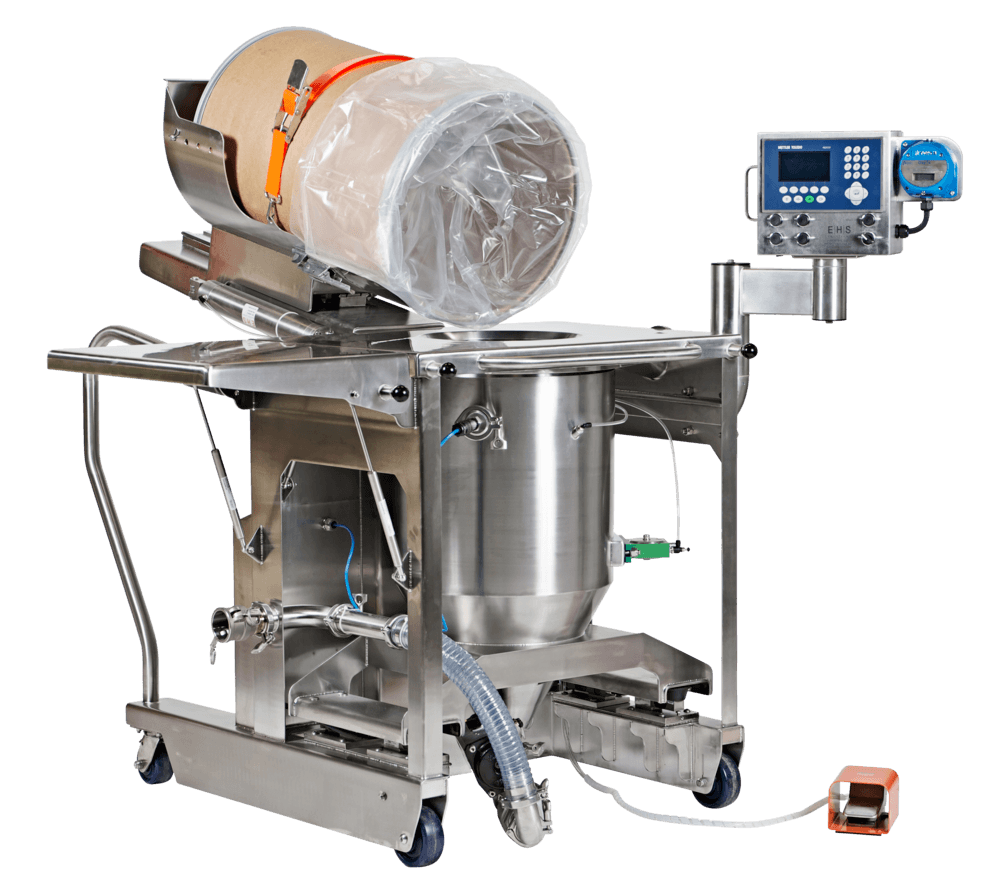

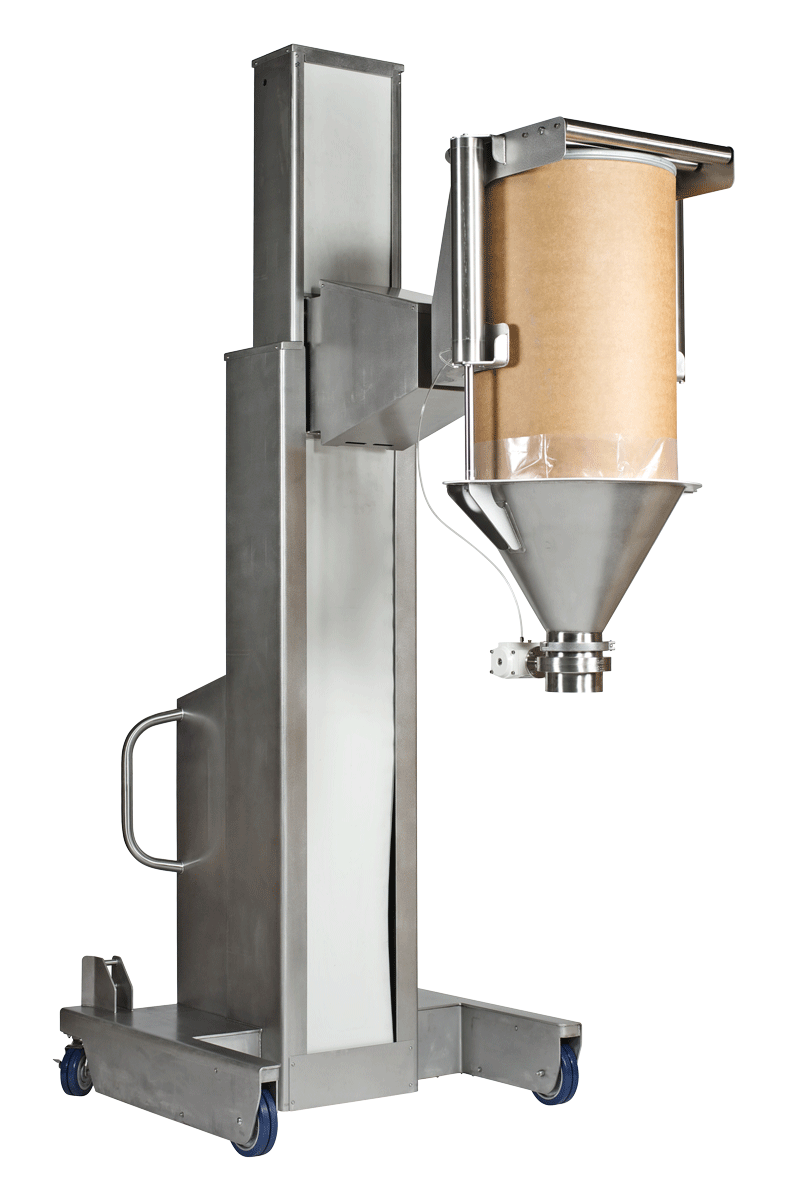

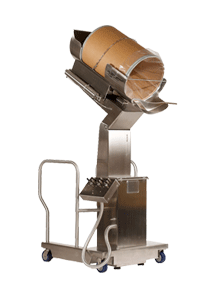

In 1997, a major pharmaceutical company had a need for drum charging and dust containment equipment for their bulk API operations. Finding no suitable solutions in the marketplace, the company’s safety team developed the Drum Charging System; an operator-friendly system that minimizes the ergonomic issues and exposure hazards associated with drum charging. EHS Solutions LLC was created by members of that safety team and it acquired the rights to the patented Drum Charging System.

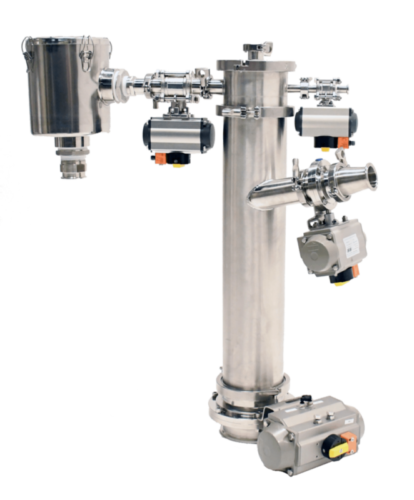

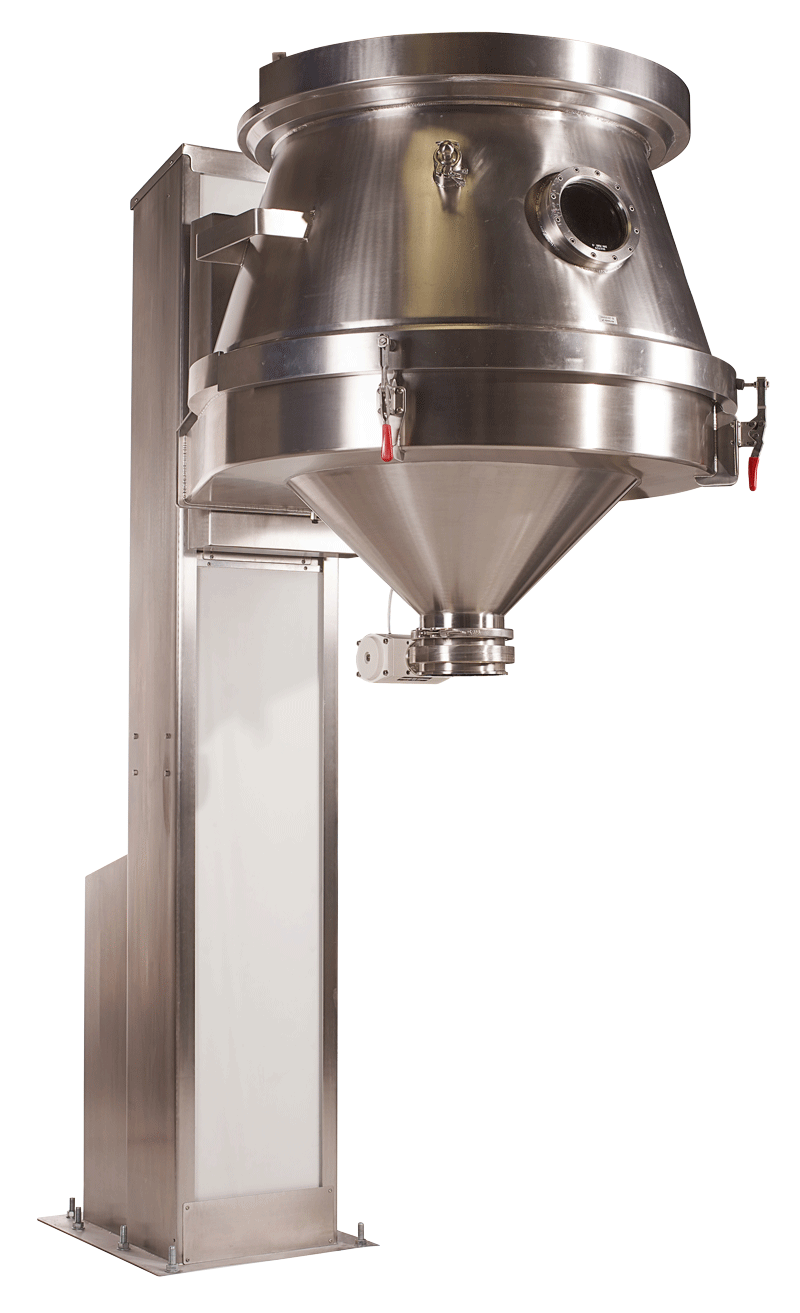

Throughout the years, EHS Solutions became a leading industry resource in customized engineering controls relating to GMP material handling, containment, inerting systems, process equipment, and custom GMP products. Its core technology has focused on material handling, point source containment, process equipment, and custom inerting systems.

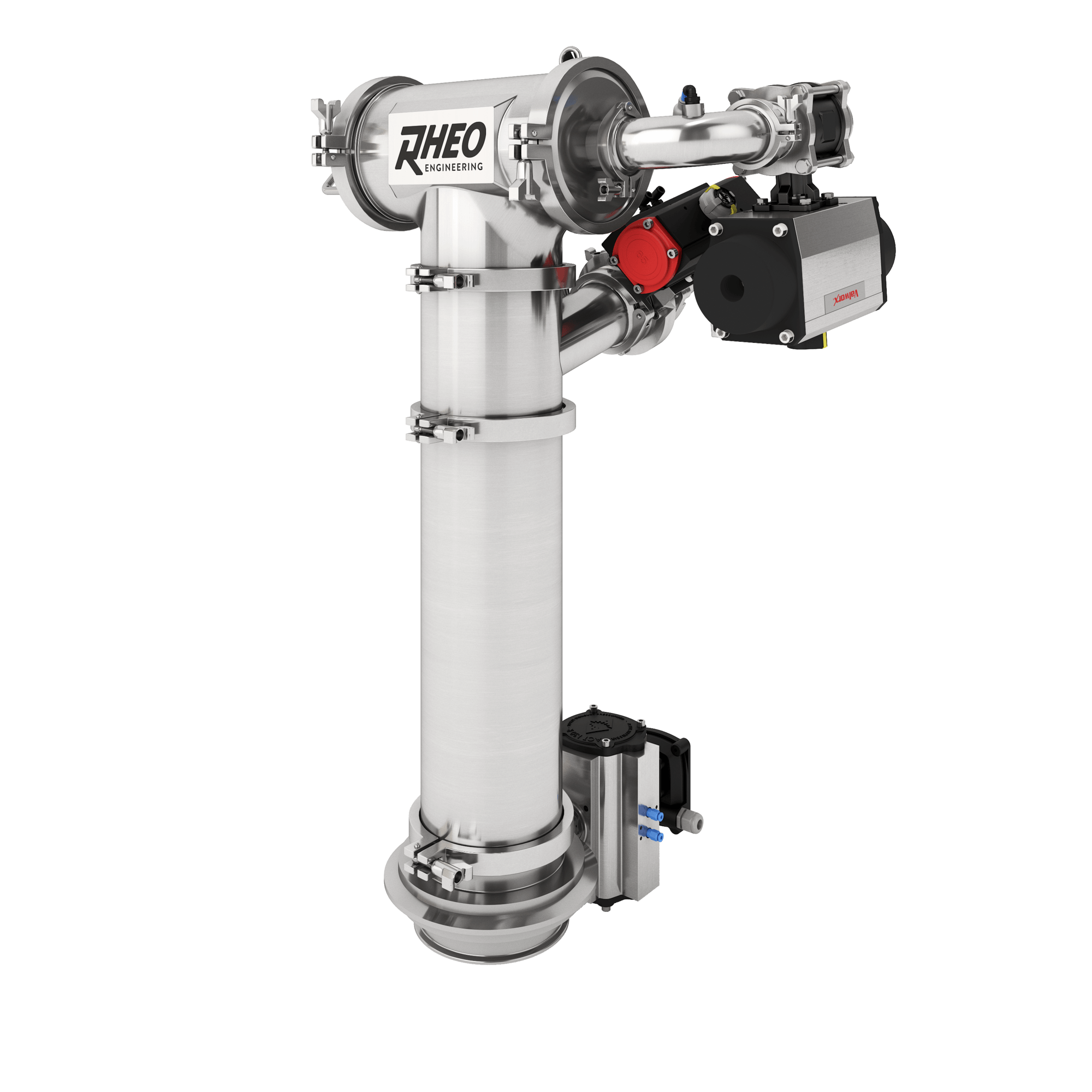

In April of 2020, EHS announced a new name for the company: Rheo Engineering. Rheo, a Greek prefix meaning “flow,” truly reflects what they are best at: designing and building large engineering systems for material flow. Over the past three decades as EHS, they became inherently identified with safety and safety solutions. While proud of that association, the capabilities and offerings of Rheo have grown far beyond safety solutions alone, making the name EHS too limiting for the organization it is today.

Rheo offers solutions that serve the needs of the pharmaceutical, specialty chemical, food and beverage, nutraceutical, and cosmetic industries – and it continues to develop customized turnkey solutions for its clients.