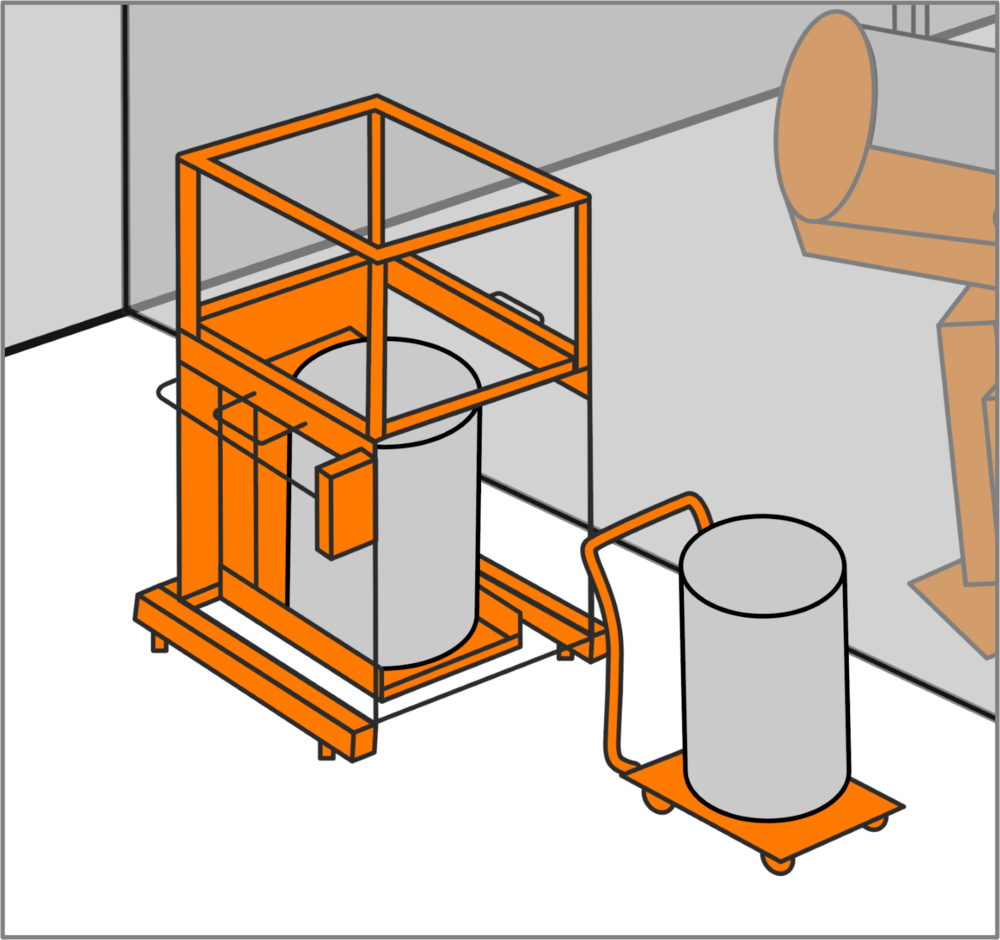

The Rheo Drum Conditioner (Drum Massager) provides a safe and reliable means of conditioning hardened product within raw material containers. The breakup of hardened product allows for easier product flow out of drums later in the manufacturing process.

Safety: Eliminates the need for a mallet or baseball bat in the product conditioning process, allowing the operator to break up material throughout the drum without removing the lid so the material stays contained.

Efficiency: Programmable recipe system conditions drums without relying on operators to manually control the machine, freeing them to perform other tasks simultaneously.

Reliability: Automatically condition drums using customized recipes to ensure repeatability with breaking up the material.

Demo Drum Conditioners Available for Trial!

Test one of our demo Drum Conditioners at your site. The first two weeks of the trial are free, you just pay shipping charges. Request a demo today by emailing sales@rheoengineering.com or click the button below and fill out the form.