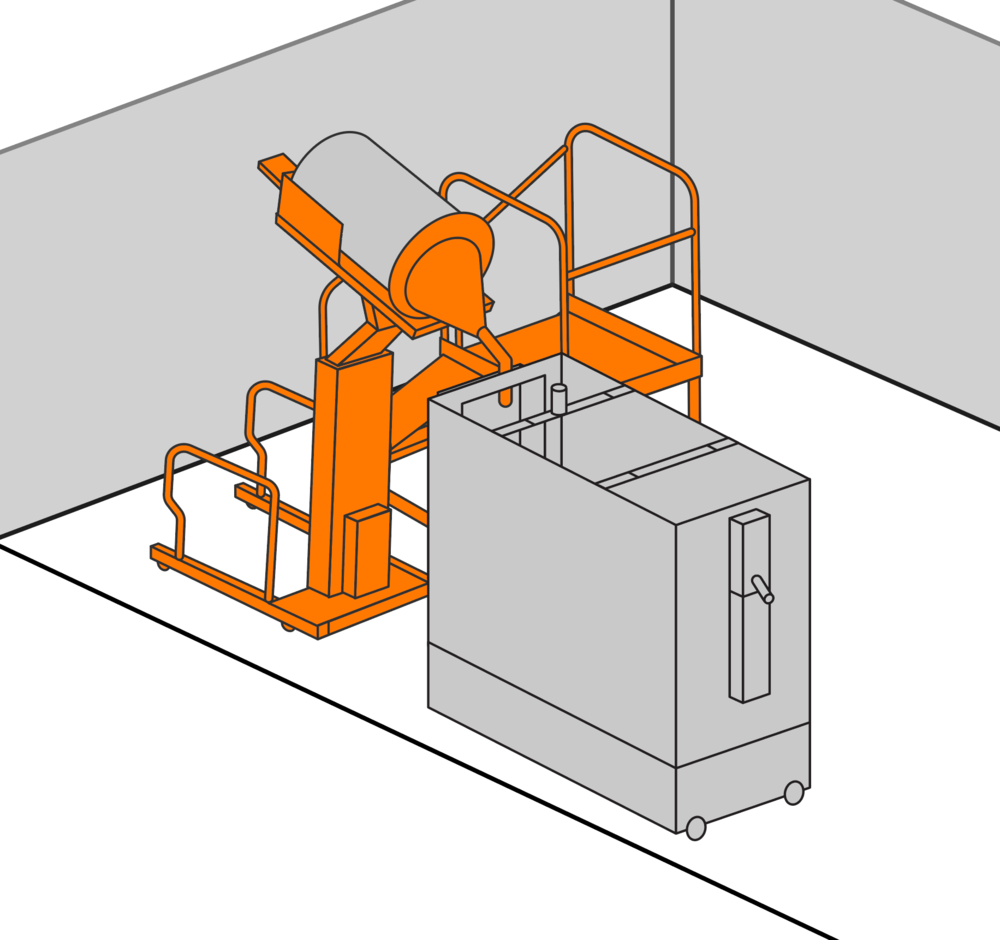

Tablet printing requires gentle handling of tablets as they are introduced into the printing machine fill hopper. Rheo offers a Variable Height Drum Tipper solution that places the drum of tablets over the fill hopper to allow a flood feed of tablets. This system is supplied with a tablet friendly control valve to control the flow of tablets into the hopper.

Tablet Printing (A)

15 seconds

Drum Tipping

200 kg

Capacity

Variable Height Drum Tipper

The Rheo Drum Tipper addresses the ergonomic risk factors associated with manually dumping drums. Each Drum Tipper is designed to meet the specific requirements of the application (drum weight, discharge height, discharge reach, etc.). When a compression cone and valve are required to facilitate a hands free, controlled transfer of free flowing powders, tablets, or capsules; the final tipping angle of the Drum Tipper is increased to 45 degrees. This design is well suited to the filling of elevated hoppers in which a self-regulating flood feed is required.

The compression funnel is available on both the standard and Variable Height Drum Tippers.

Operator Platform

Rheo can provide a GMP and OSHA approved operator platform that is designed for your process.

Tablet Printing (B)

Tablet Printing (B)