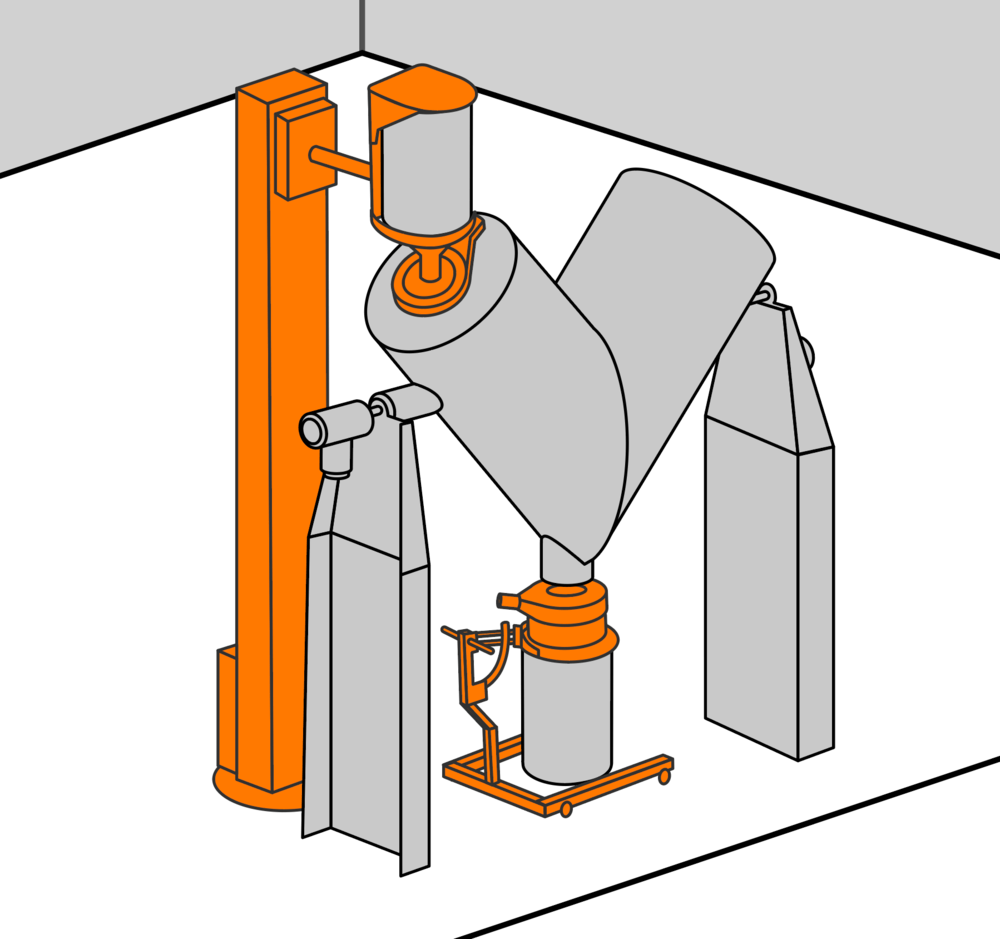

Loading product into V-Blenders is a common challenge that can introduce multiple operator safety risks. Lifting and dumping drum or bag stock into the opening of a V-Blender is a difficult task that can expose operator to high levels of airborne dust and create awkward lifting postures that can lead to operator injury. If your blender can support full vacuum pressure, the Vacuum Transfer Station provides an ergonomic workstation with an integrated Drum Tipper and vacuum transfer hopper. Rheo can also provide an independent vacuum conveyance system if the blender cannot support full vacuum. The emptying process of the blender is often a very dusty process that can be significantly improved by using the Mobile Ventilation Sleeve for local dust extraction.

V-Blending (A)

100-10μg/m³

Containment

500cfm

Point Source Capture

75 kg/minute

Product Transfer Time

Vacuum Transfer Station

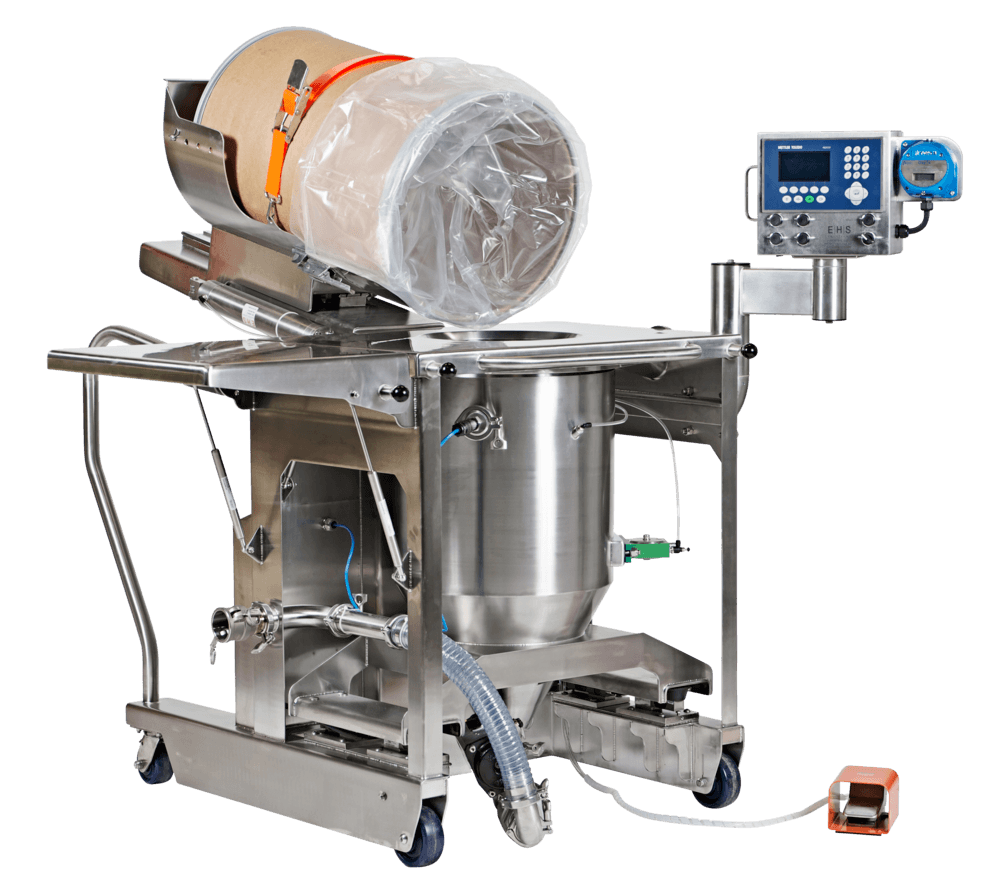

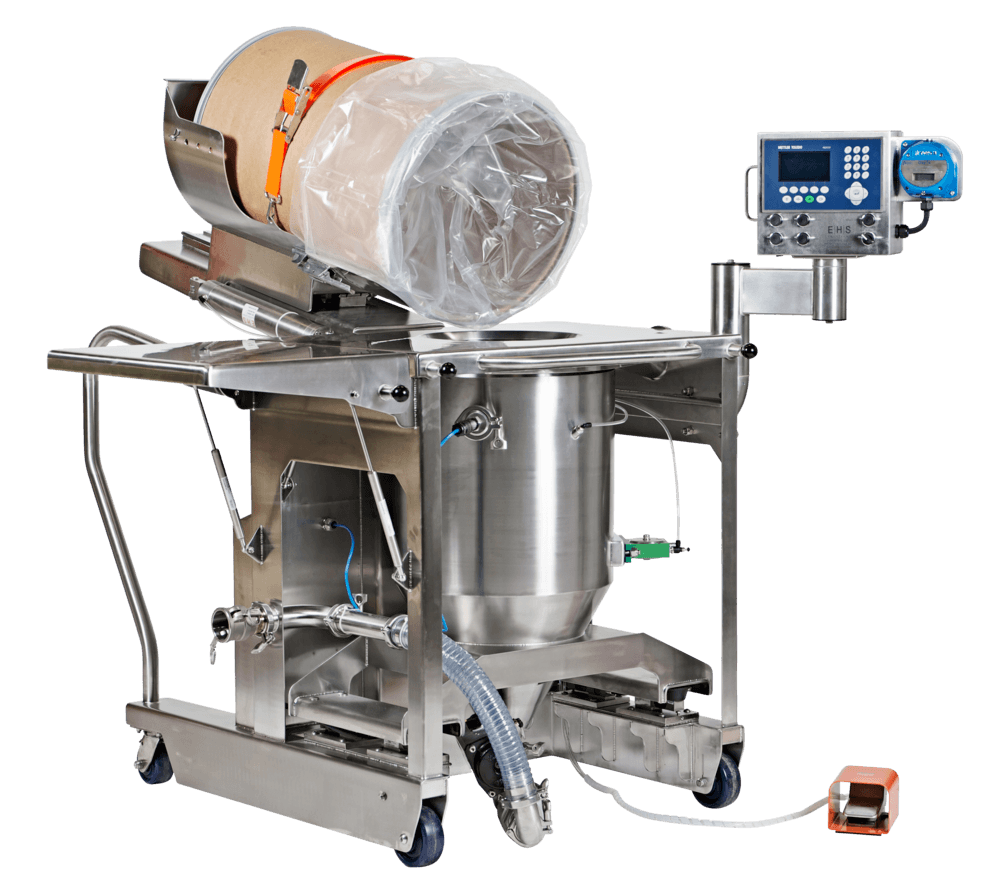

The portable Rheo Vacuum Transfer Station features a small footprint that optimizes ergonomics and the functional requirements of a vacuum transfer system. The integrated Drum Tipper and vacuum hopper eliminate the ergonomic and exposure issues associated with open manway charging. The Vacuum Transfer Station can be configured to achieve containment levels of less than 1 μg/m³.

This Vacuum Transfer Station can utilize the evacuated vessel or PTS pump to carry out the powder transfer. Nitrogen inertion can also be achieved during the vacuum transfer of powders.

Mobile Ventilation Sleeve

The Rheo Ventilation Sleeve provides localized dust extraction to capture airborne dust and vapor. The full perimeter slot design provides 360 degrees of extraction to ensure that the required capture velocity is achieved across the entire opening of the Ventilation Sleeve. Each Ventilation Sleeve is engineered to interface with the equipment it serves.

The Rheo Mobile Ventilation Sleeve allows the Rheo Ventilation Sleeve to be portable and utilizes a simple linkage design that makes the height adjustable.

The integrated transport cart allows the Ventilation Sleeve to be easily moved from one location to another. A lift-assist mechanism attaches the Ventilation Sleeve to the transport cart, allowing the height of the Ventilation Sleeve to be adjusted.

Air Filtration Unit (Supporting Product)

Rheo offers a complete line of portable and stationary Air Filtration Units that provide a local HEPA filtration device to serve Local Exhaust Ventilation (LEV) systems. The Rheo Air Filtration Unit is designed to meet the utility requirements of multiple Rheo Ventilation Sleeves; it is also a good fit for any application with similar extraction utility requirements.

Each system is configured to comply with international electrical standards. The GMP compliant design features a small footprint and noise rating of 76 dBa. Safe Change filters and activated carbon filters for VOC’s are also available.

Rheo Air Filtration Units are a cost effective alternative to upgrading house exhaust systems that have become over utilized or where there is a need to prevent the contamination of the house exhaust system ducting.

Vacuum Conveyance System (Supporting Product)

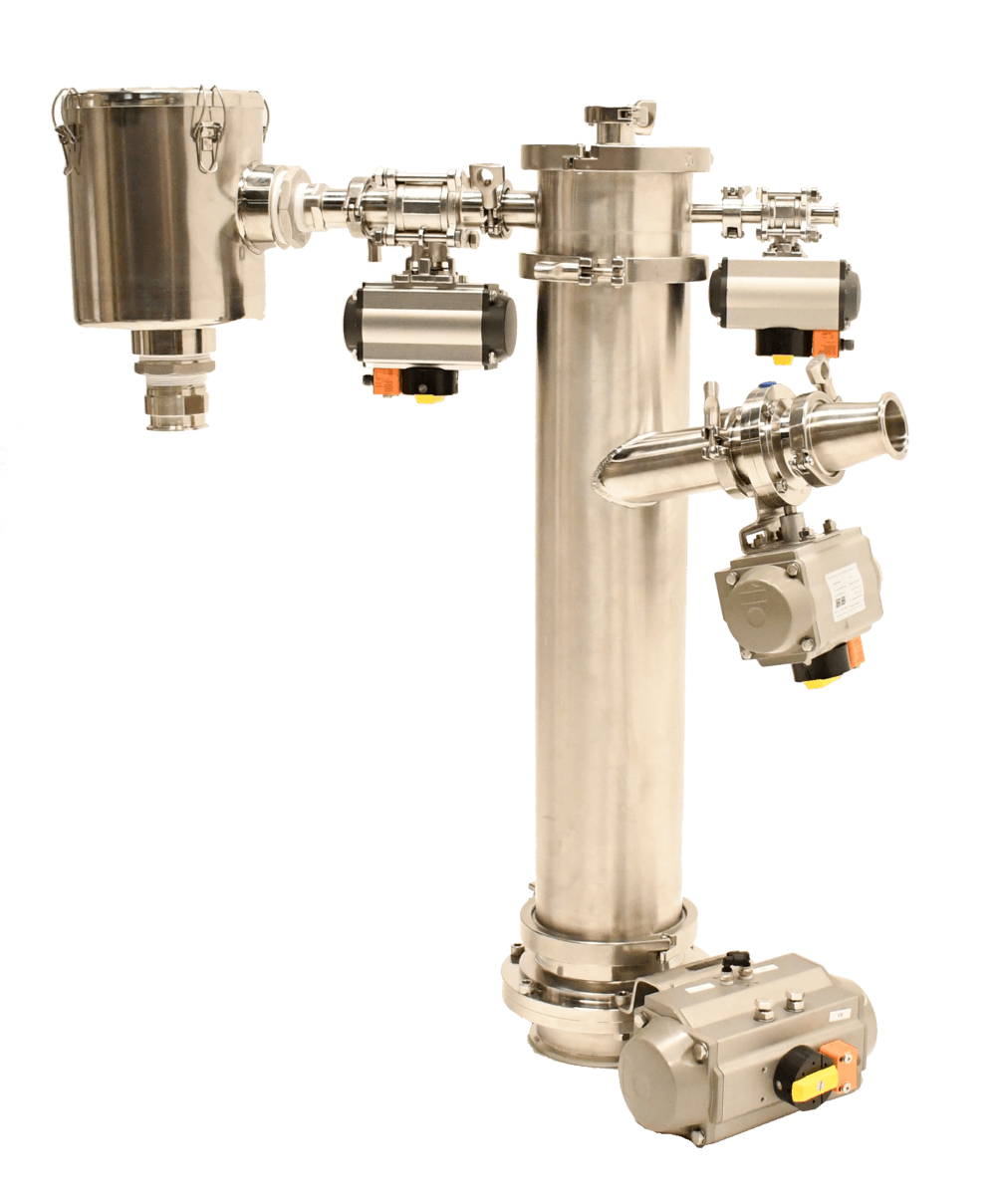

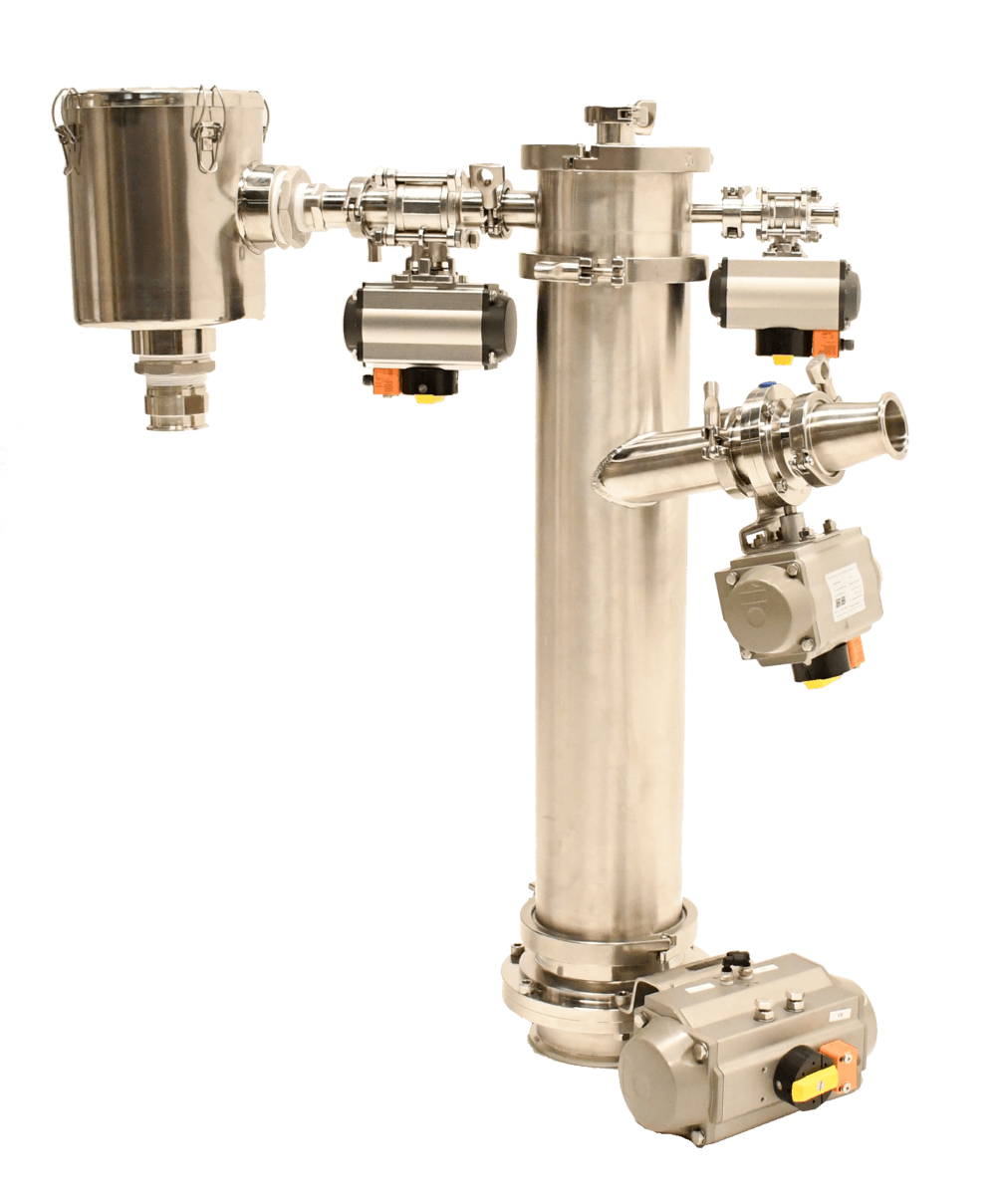

The Rheo Vacuum Conveyance System [VCS] provides a safe, efficient, and contained means for transferring material using a vacuum source instead of relying on gravity. The VCS is ideal for transferring highly toxic or potentially explosive powders that are present in the pharmaceutical, food, and chemical industries. Safety, containment, and productivity are all addressed with this simple to use machine.

V-Blending (B)

V-Blending (B) V-Blending (C)

V-Blending (C) V-Blending (D)

V-Blending (D)