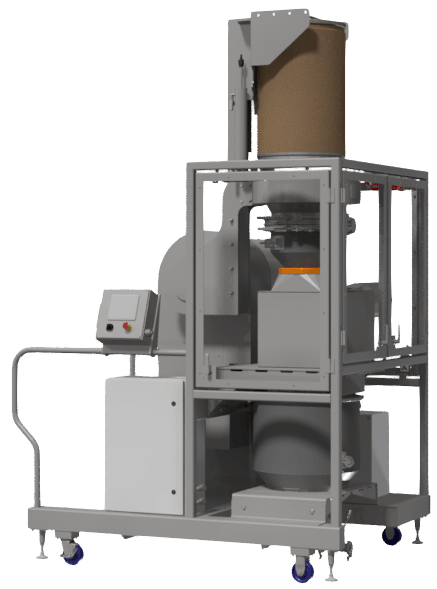

The Drum Unloading Station is designed to automatically transfer bulk solids from drums of various sizes into a vacuum hopper. Utilizing the integrated pivoting arm, the drum is secured and inverted to mate with the containment chute and grinder. Material flow from the drum is controlled by a pneumatically actuated butterfly valve as it enters the grinder. The grinder is used to reduce the material particle size to less than 5mm (~1/4”) in order to optimize the vacuum conveyance. Laser sensors in the vacuum hopper monitor the hopper volume to know how much product has been transferred or when the drum is emptied. If product flow stops before the proper amount of product has been emptied from the drum, a pneumatic vibrator automatically turns on and the butterfly valve is cycled to assist in dislodging any clogged product as it exits the drum. This machine is equipped with four safety interlock doors, which must be closed before running any function on this system.