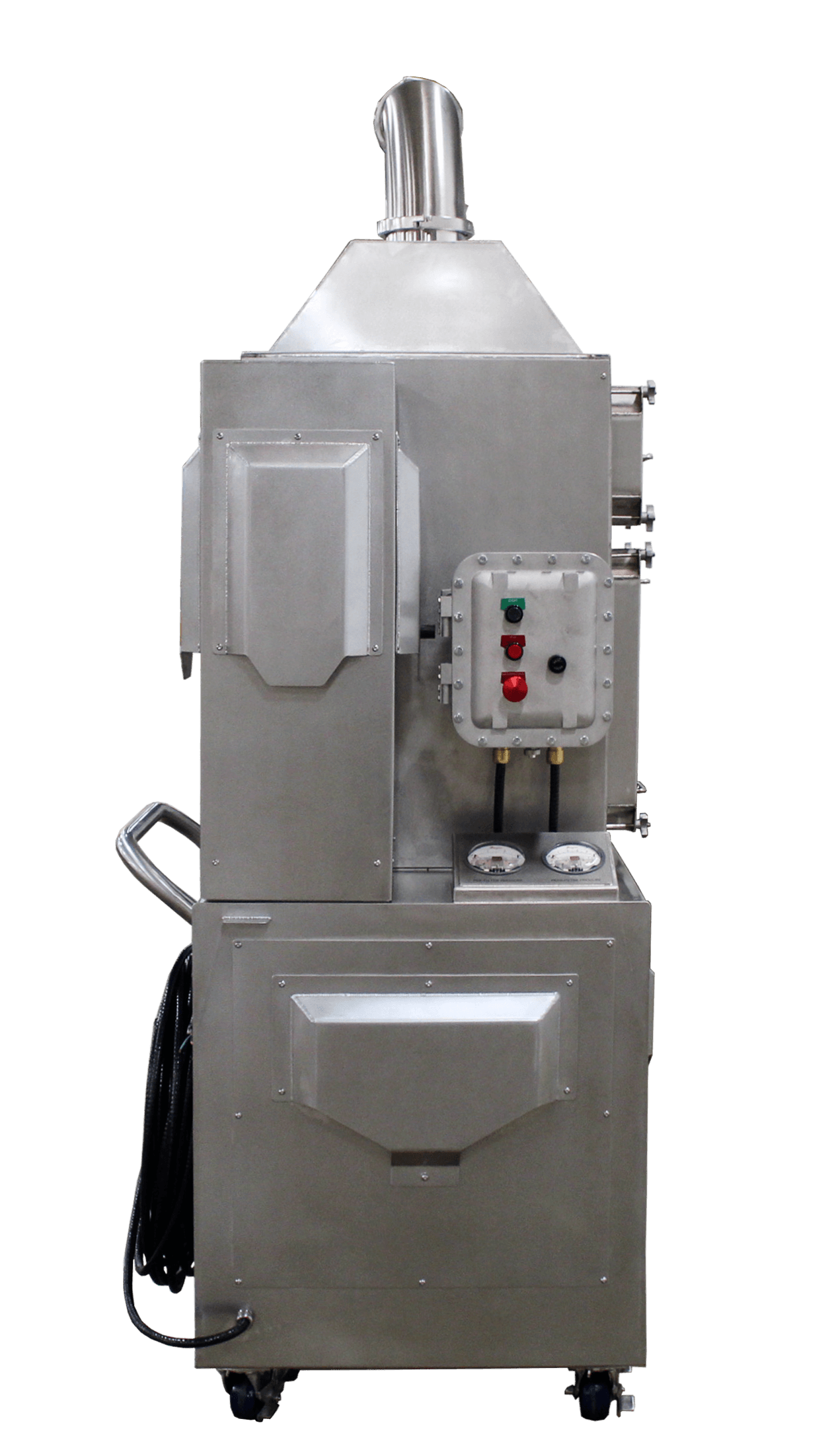

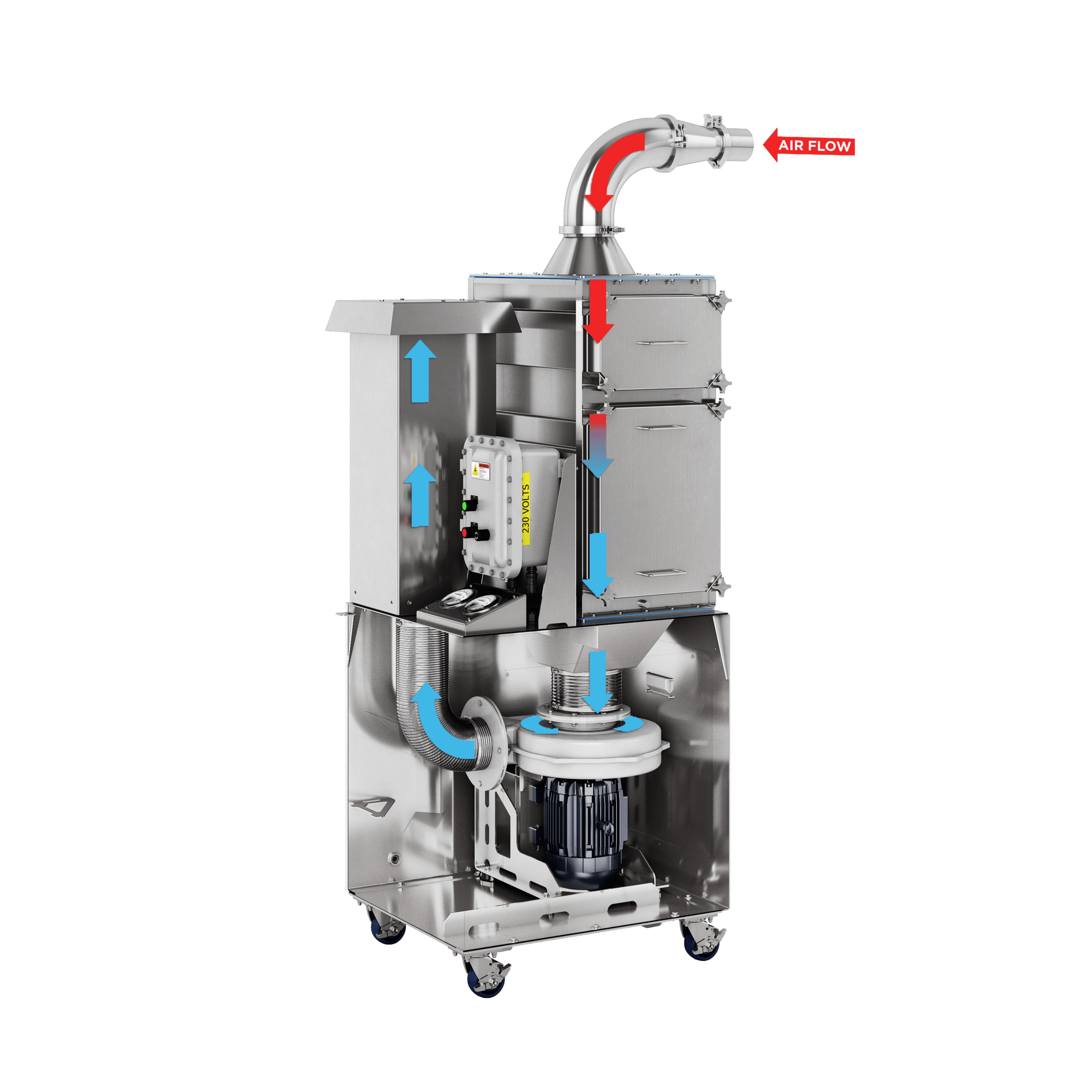

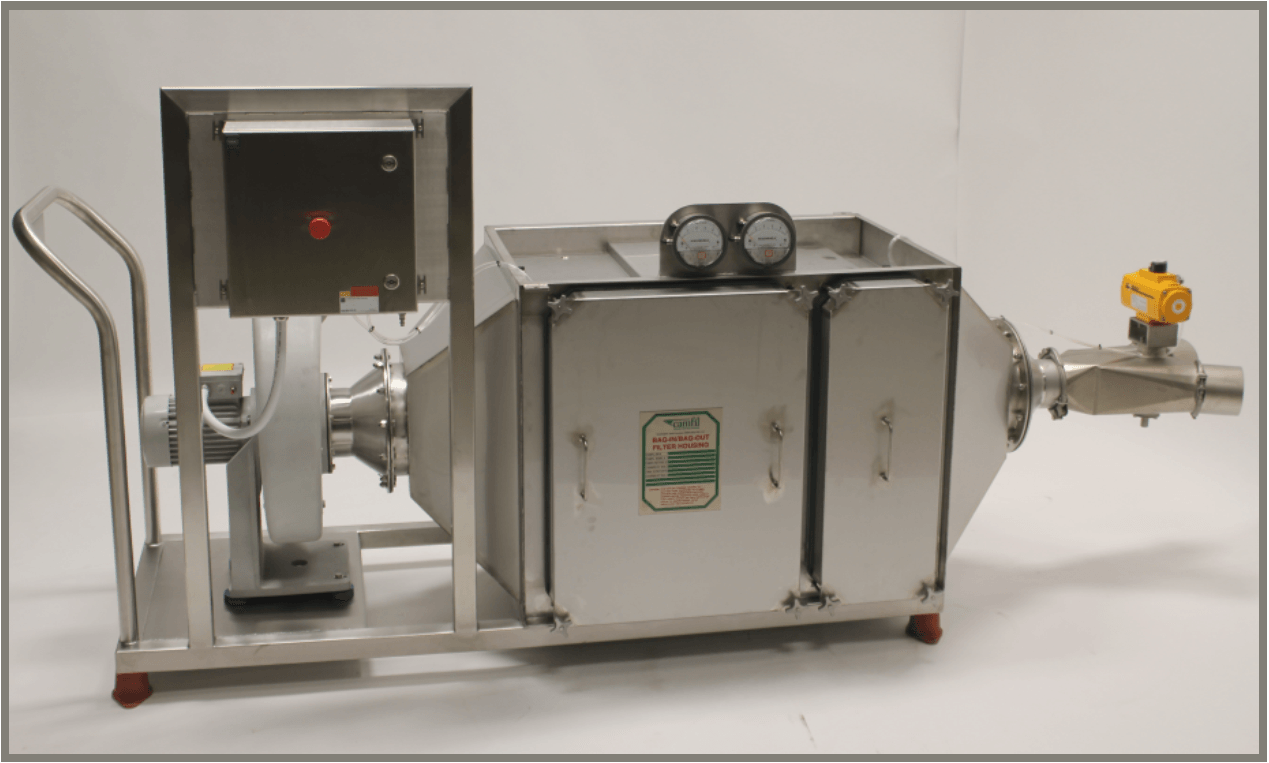

Rheo offers a complete line of portable and stationary Air Filtration Units that provide a local HEPA filtration device to serve Local Exhaust Ventilation (LEV) systems. The Rheo Air Filtration Unit is designed specifically for our Ventilation Sleeves; it is also a good fit for any application with similar extraction utility requirements. The Rheo Air Filtration Unit product line is engineered and built to order to suit your application, with many different options and configurations available.

The Rheo engineering team uses our design software and evaluation process to establish the proper air flow and duct size to ensure that your LEV will work effectively. You can contact your local account manager to set up a project evaluation meeting with one of our engineers.

Rheo manufacturers and assembles our Air Filtration Units in the United States. Declarations of conformity for local machinery directive compliance ships with every unit and can be made available upon request.

The Air Filtration Unit is commonly used when an existing house system is inadequate to provide the required flow for an application or to prevent the contamination of the house exhaust system when handling toxic compounds. It can also serve as a back-up option to continue operations when the house exhaust system is down for maintenance.