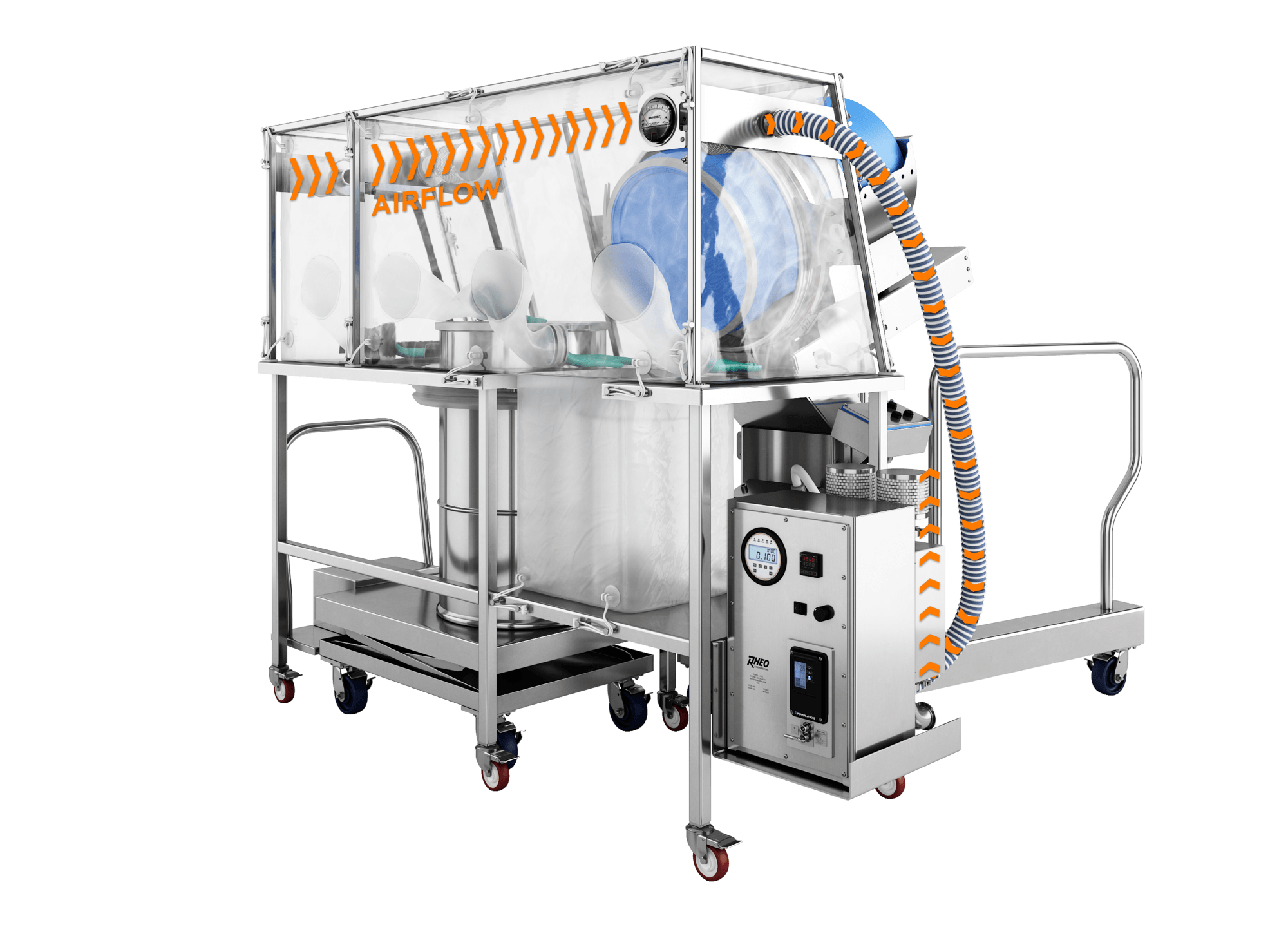

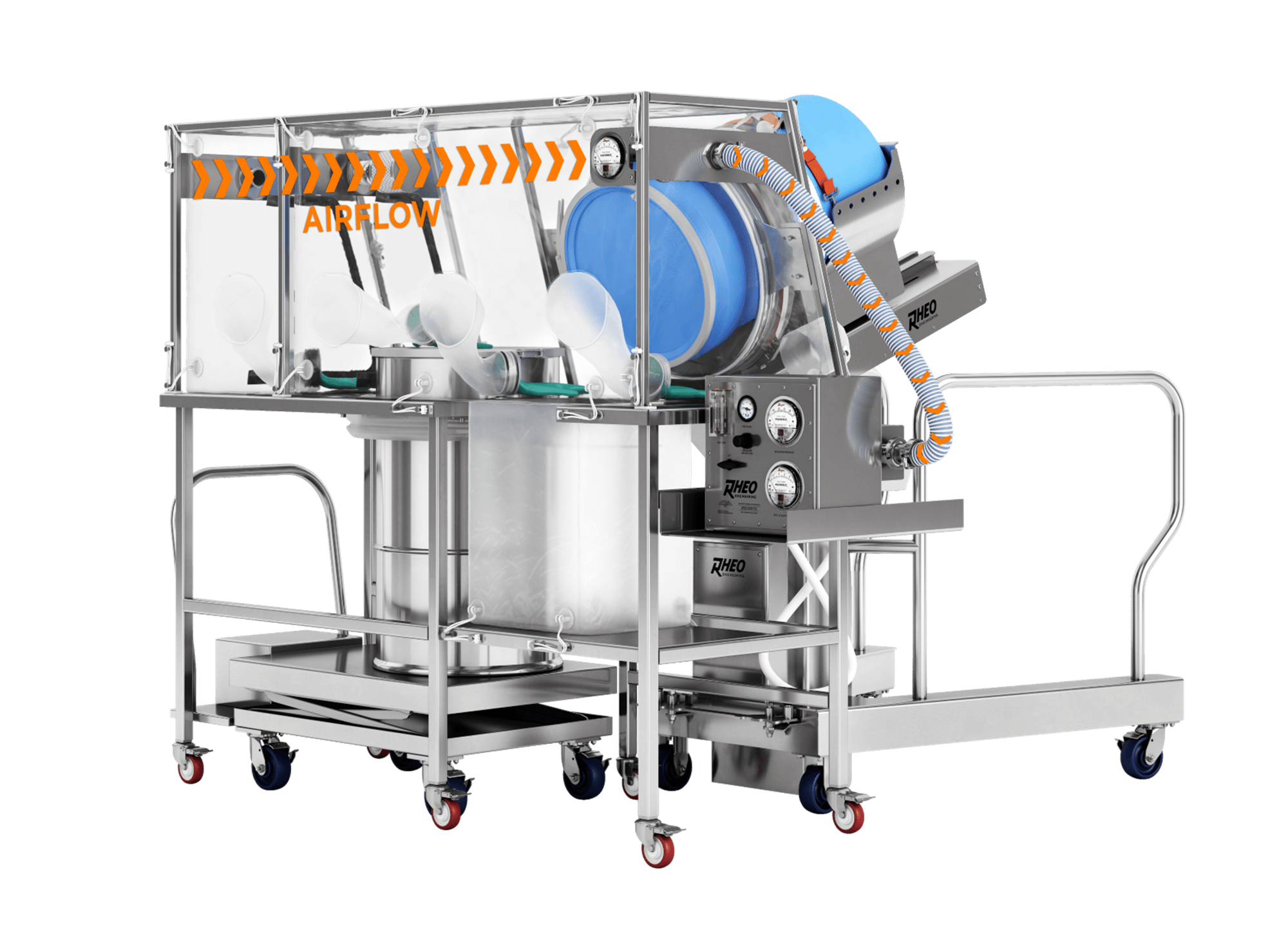

The RheoFan Unit provides dedicated air extraction for flexible or rigid isolators, creating a “dynamic” enclosure engineered to achieve containment levels as a low as 0.01 µg/m3. The automated breach response adds another layer of safety by providing an in-draft air velocity of 125 feet per minute, satisfying AGS-G001-2007 §5.6.1 and ensuring safe handling of potent and highly potent compounds.

Safety: Adheres to American Glovebox Society (AGS) air flow recommendations to maximize operator safety.

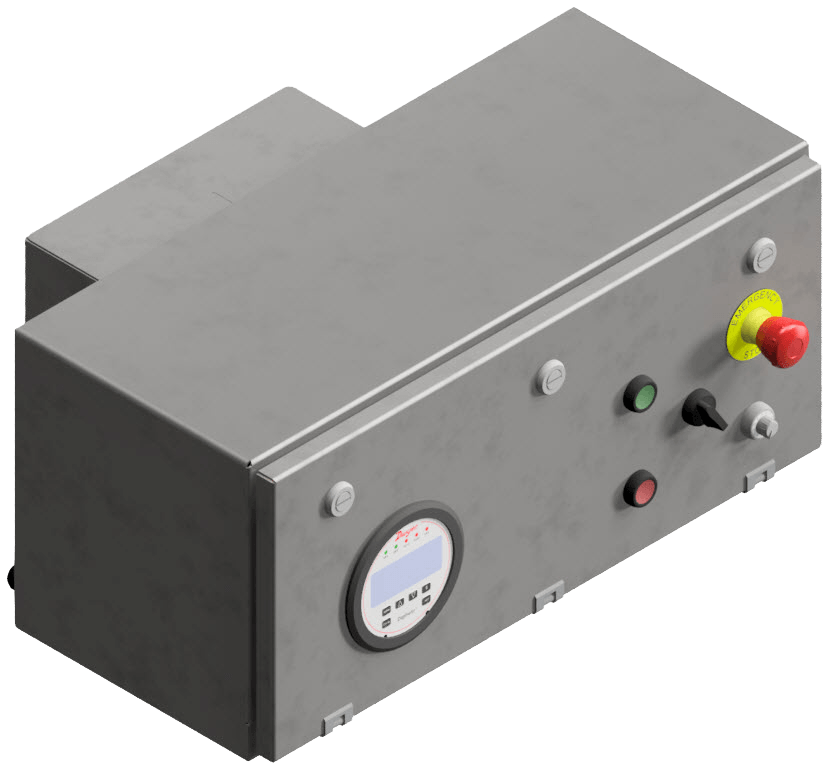

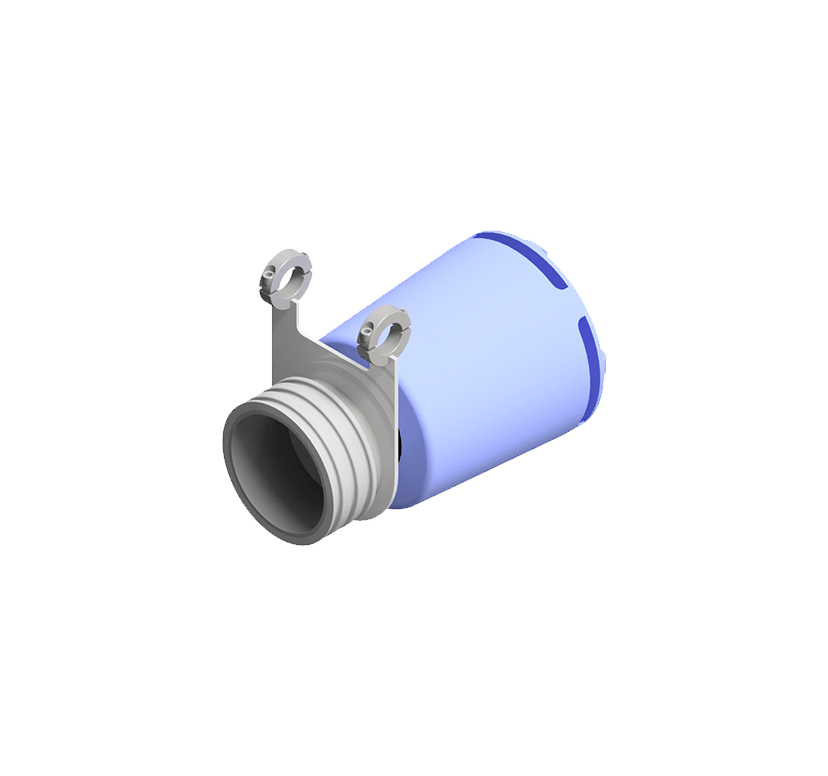

Efficiency: Automated pressure adjustment and push-through filter changeouts enable operators to focus on the dispensing task at hand.

Reliability: Robust fan and control components reduce risk of machine downtime. Durable stainless steel construction.