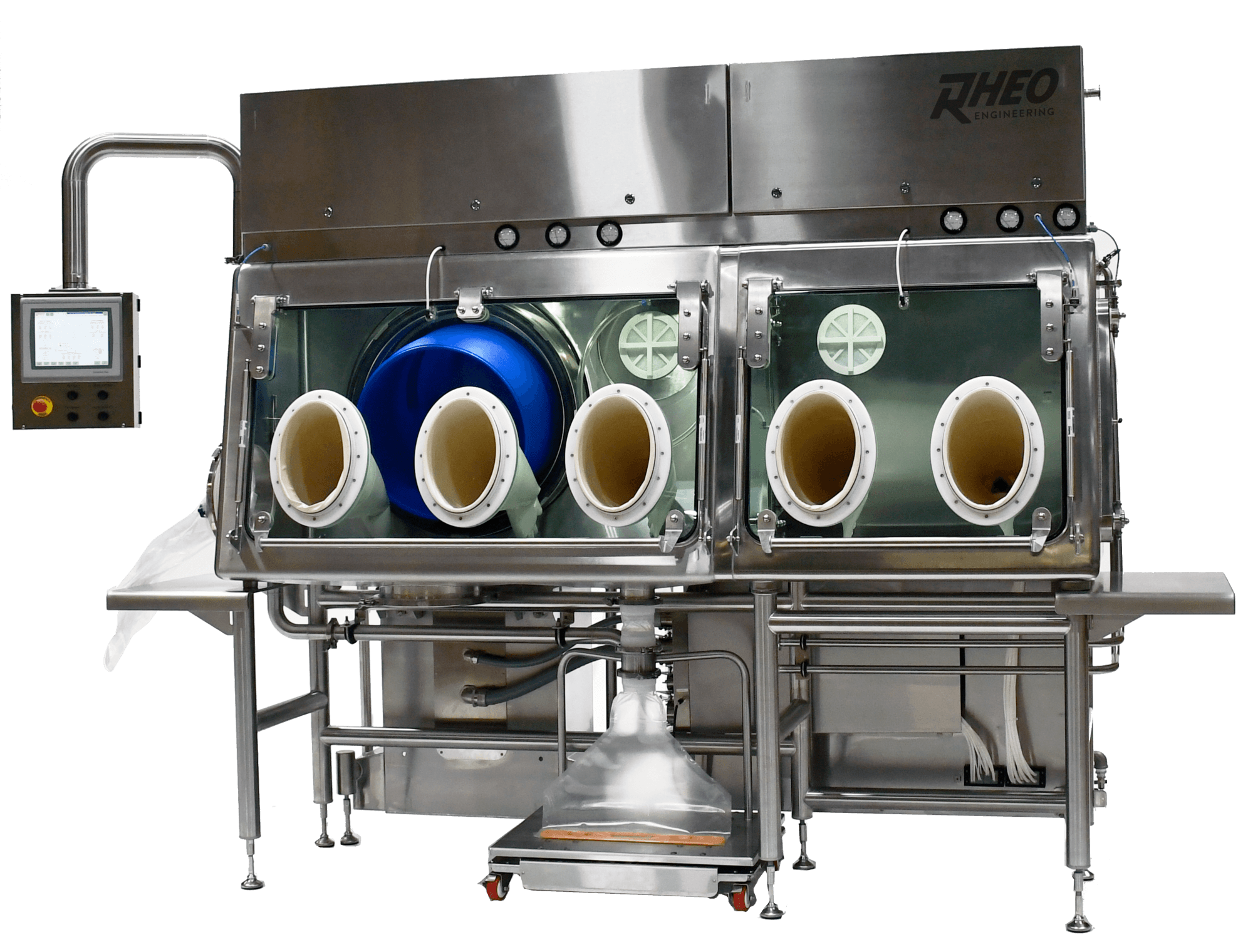

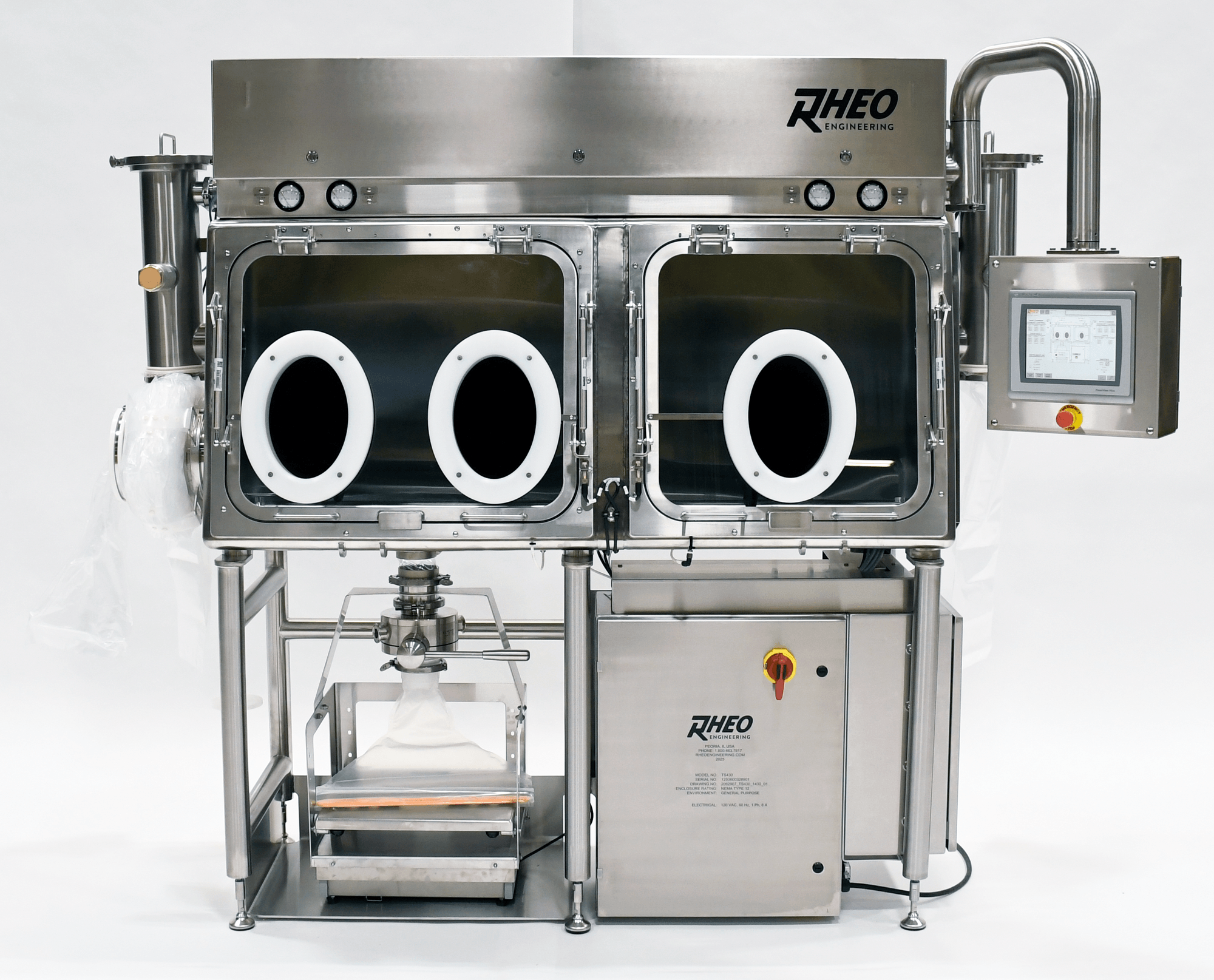

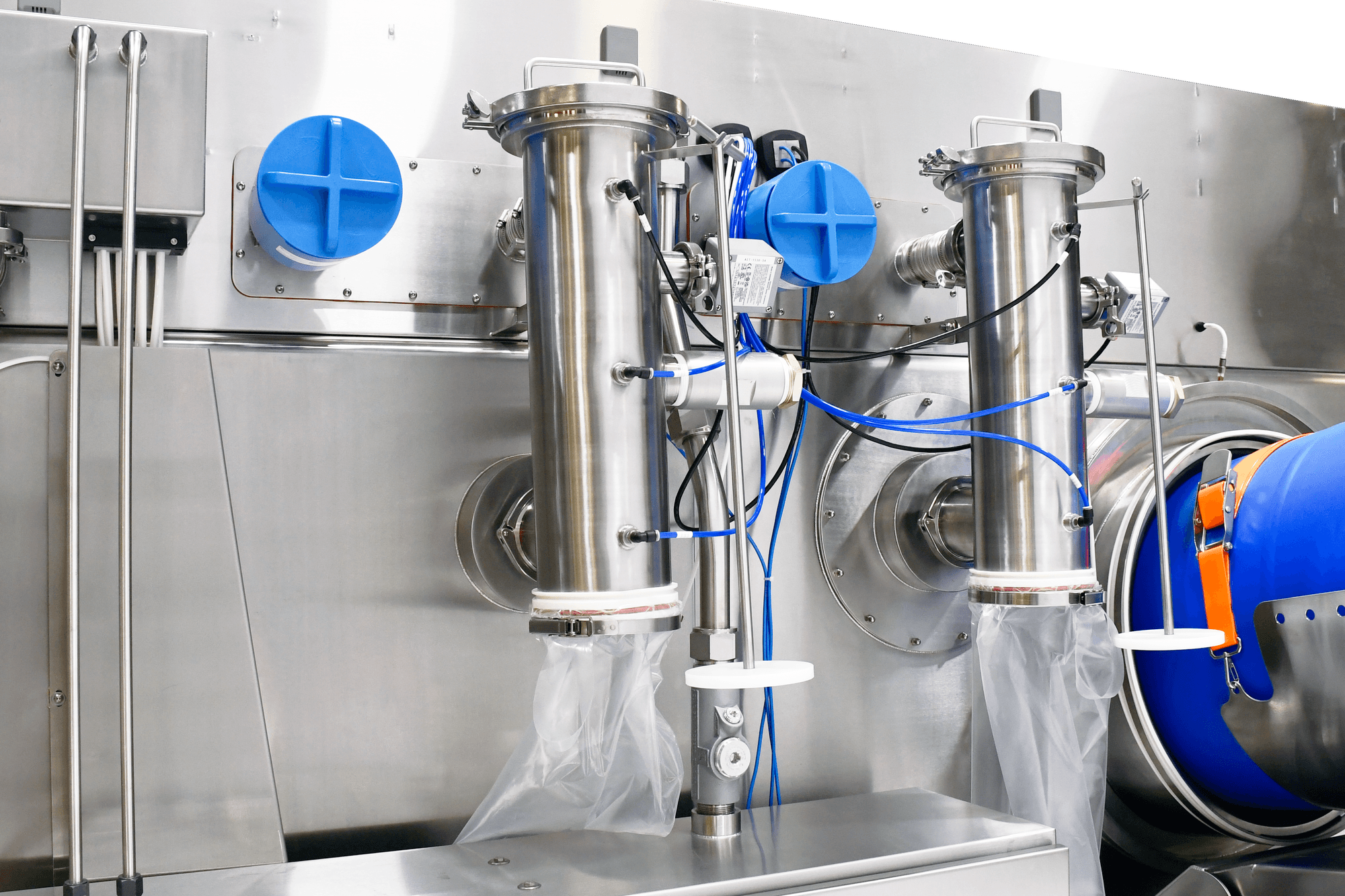

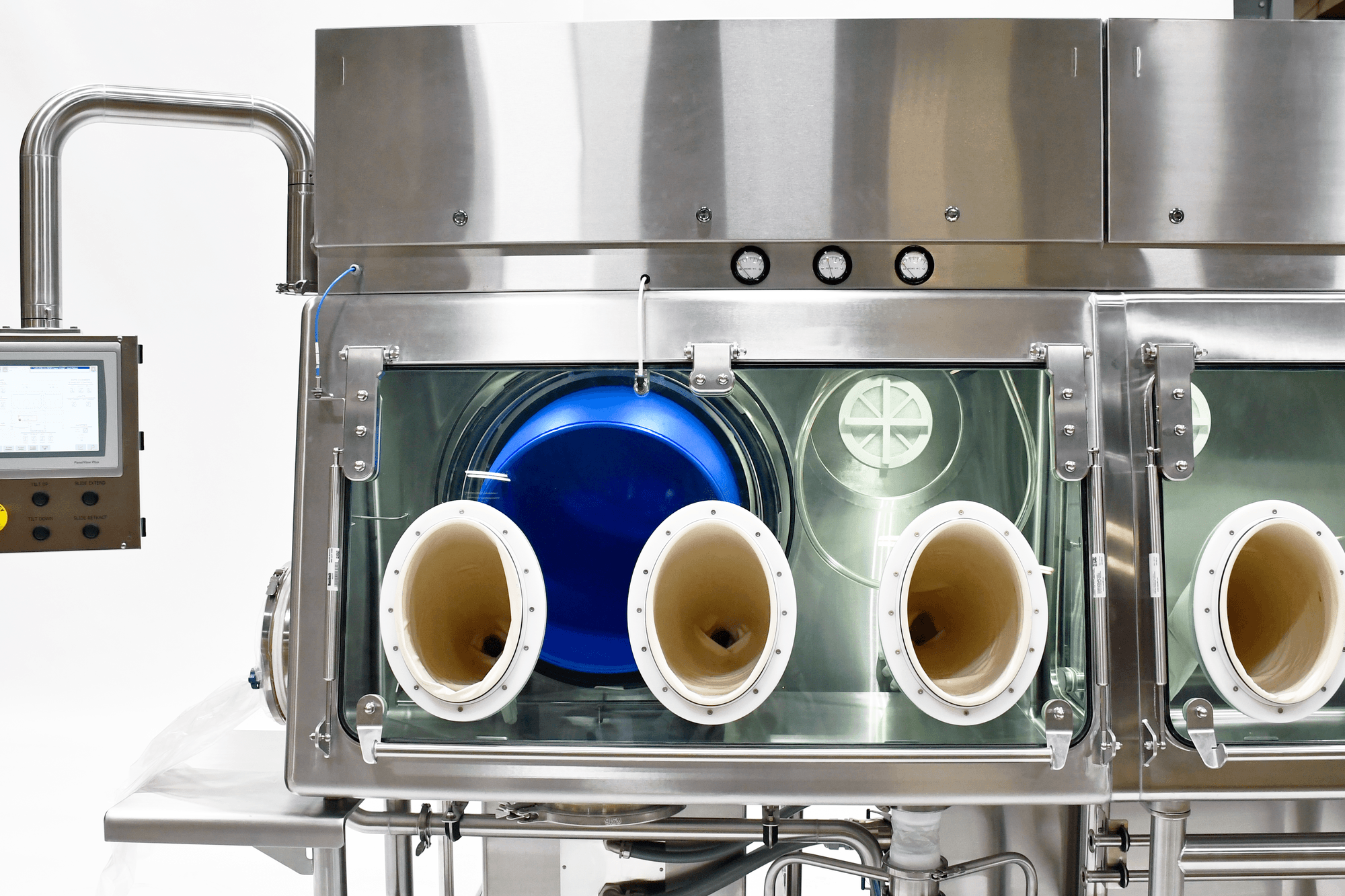

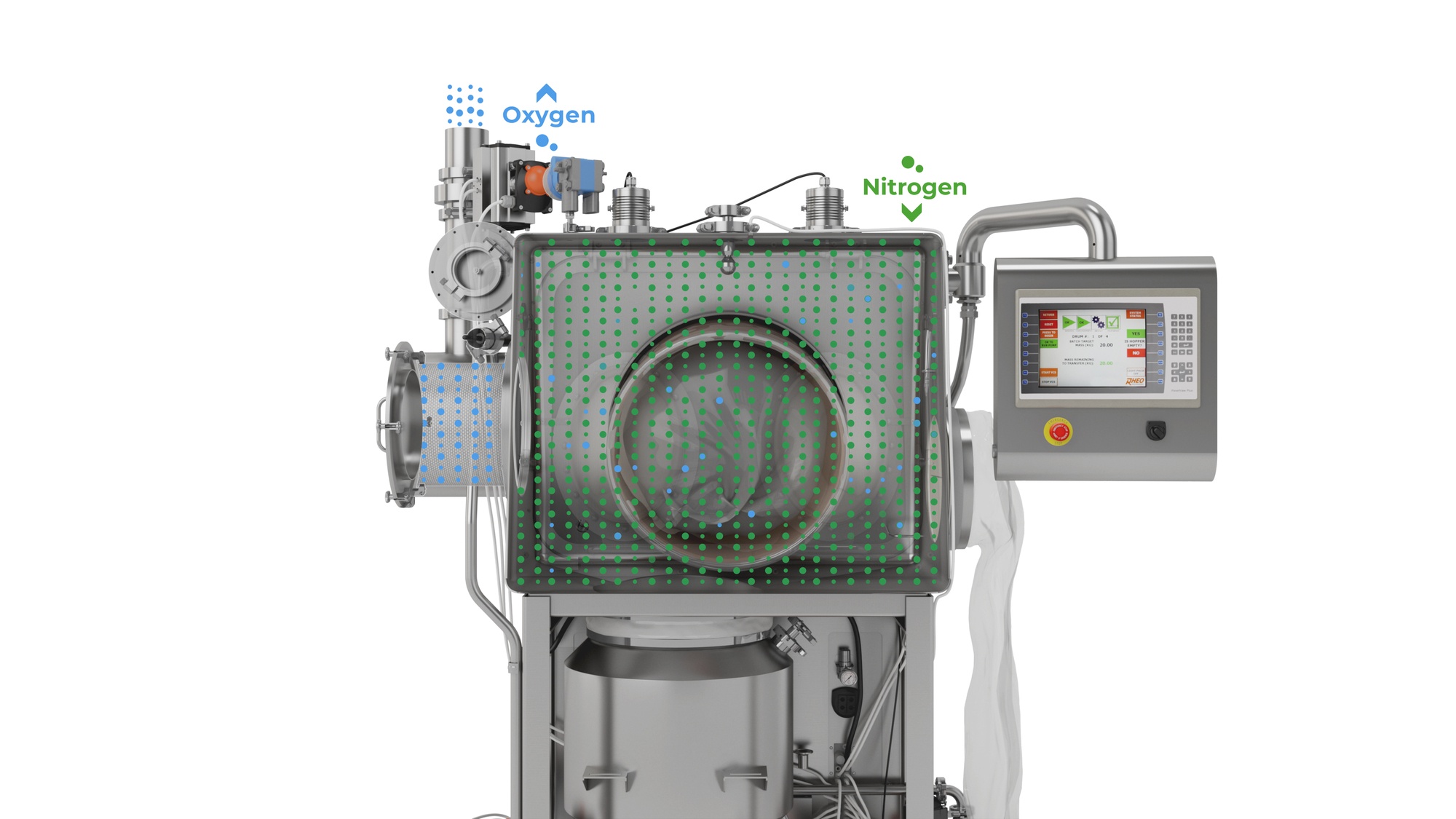

Rheo Containment Isolators provide safe environments for potent and/or hazardous material handling. Our isolator systems are built to order for your application needs.

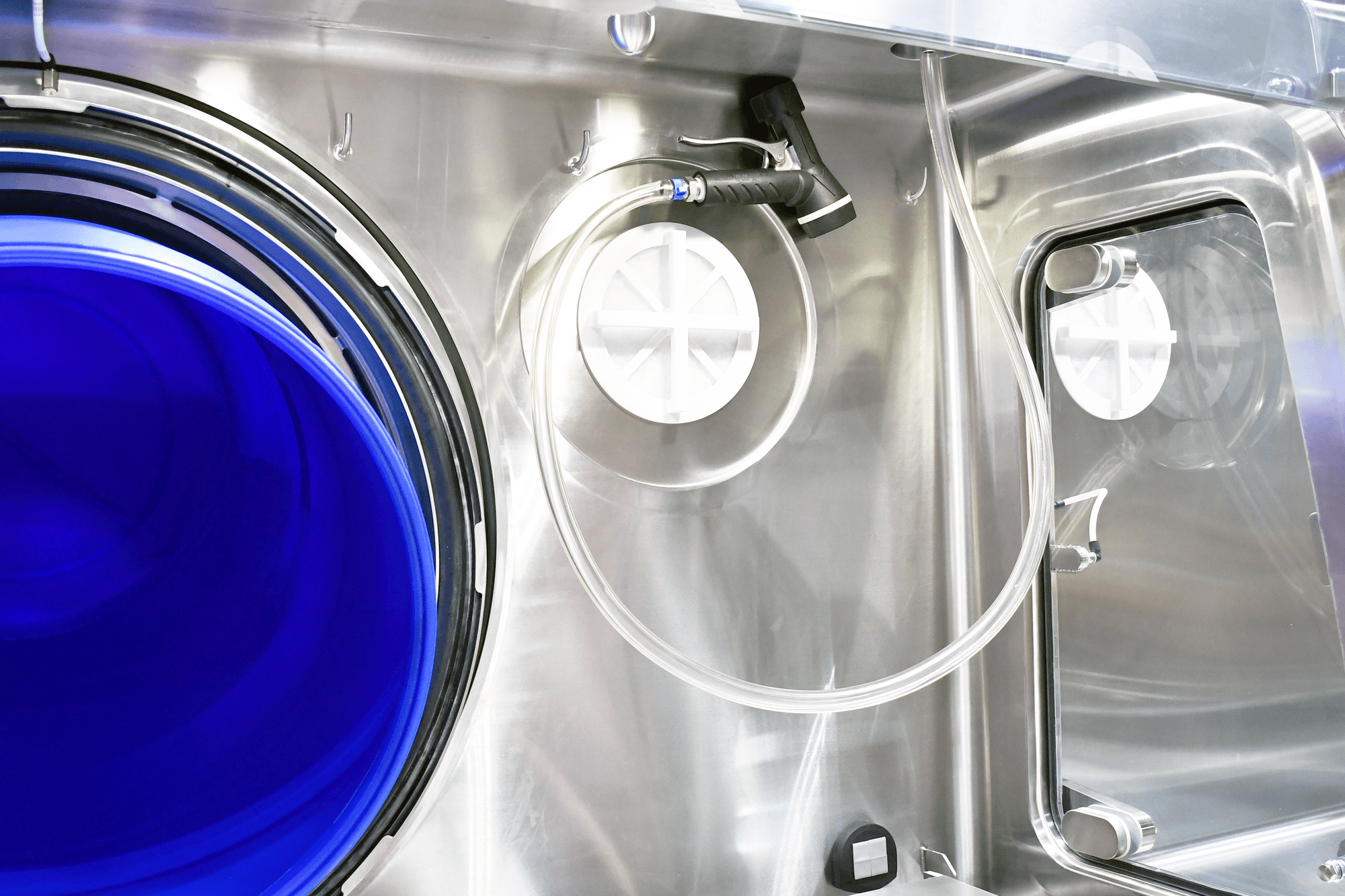

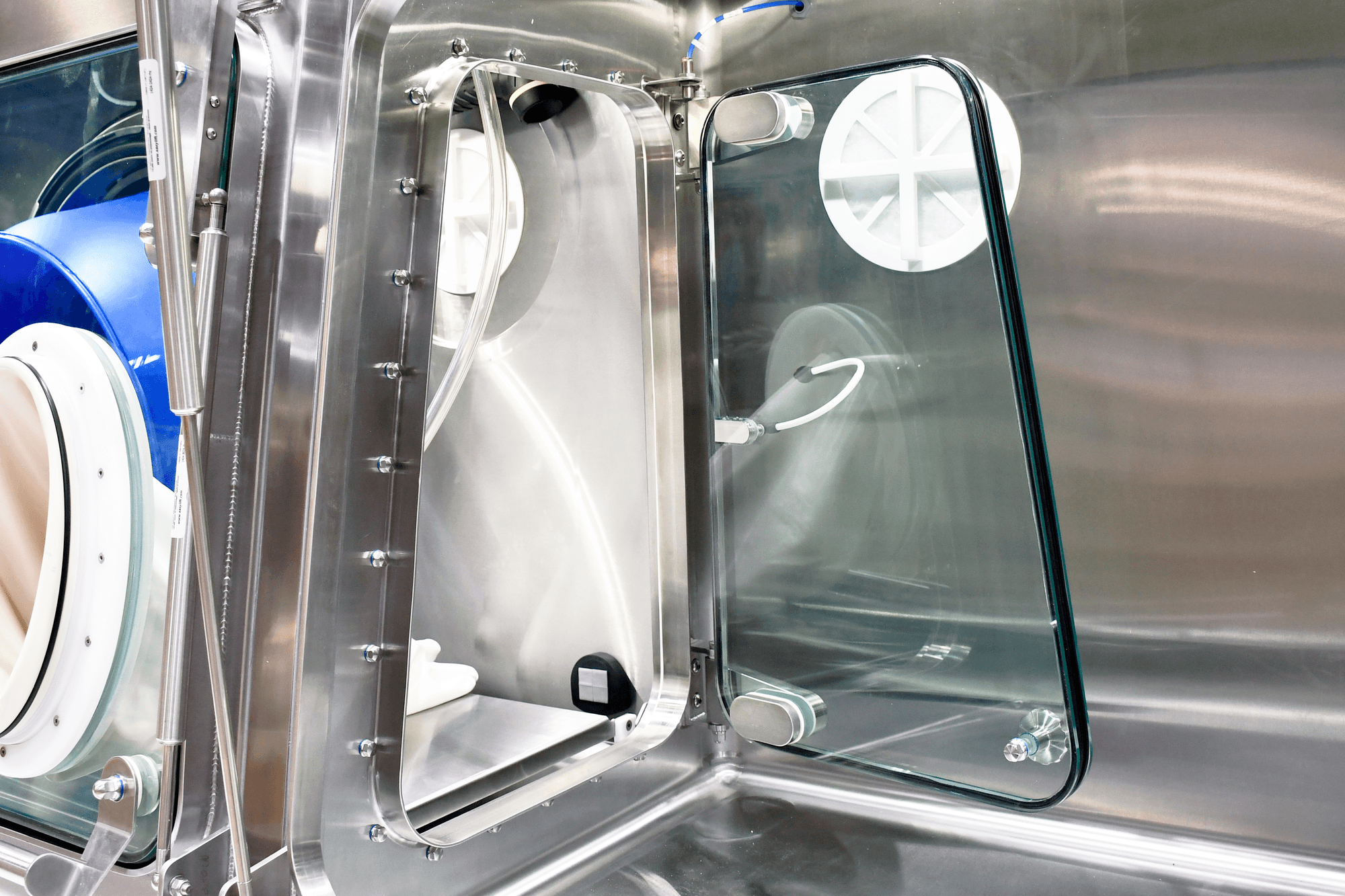

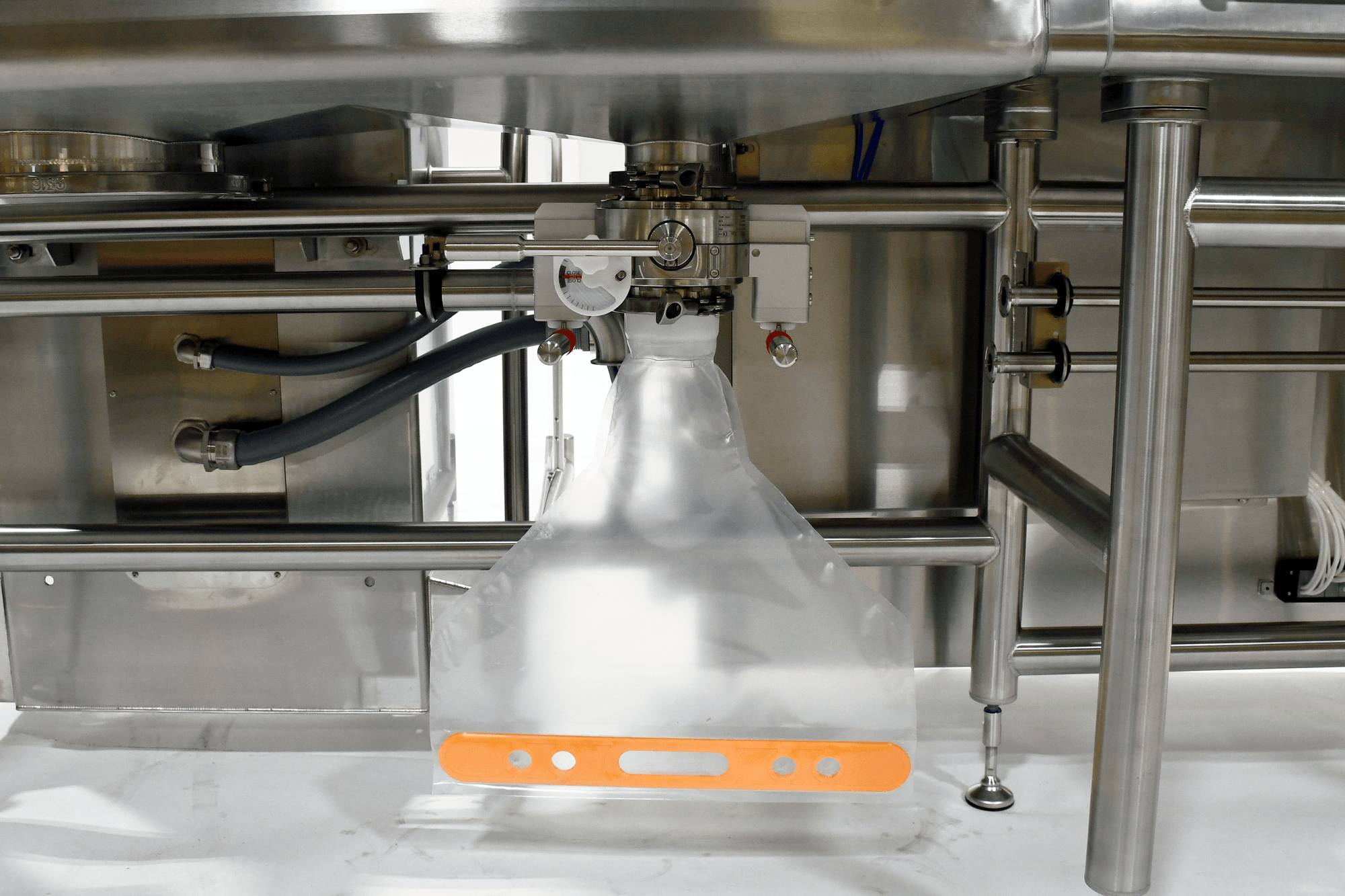

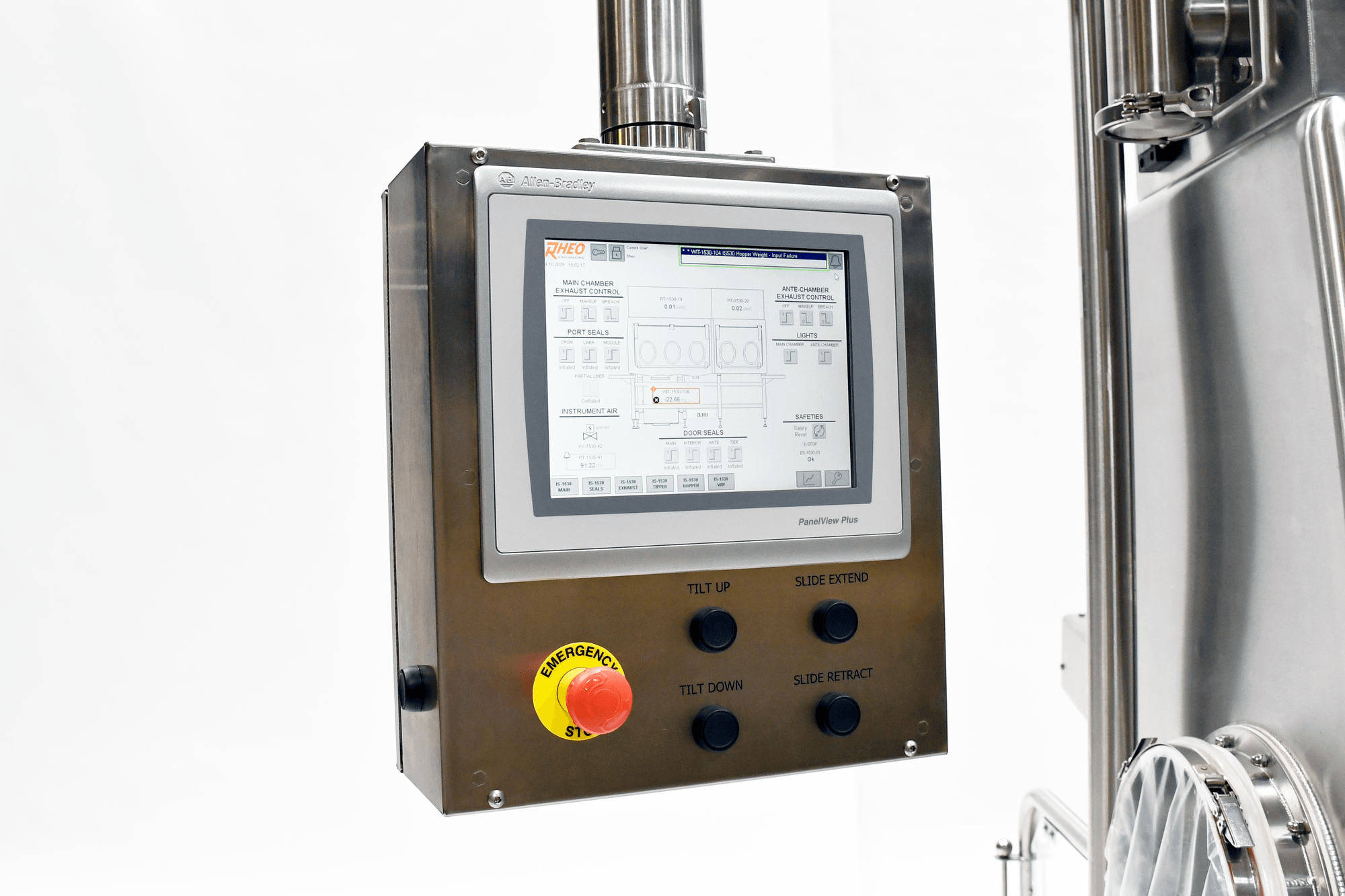

Safety: Rheo’s Isolator systems feature full environmental control to protect both operator and product, achieving containment levels of less than 50 ng/m3. Recipe setpoints for negative pressure, LOC (limiting oxygen concentration), RH (relative humidity), and more ensure straightforward operation.

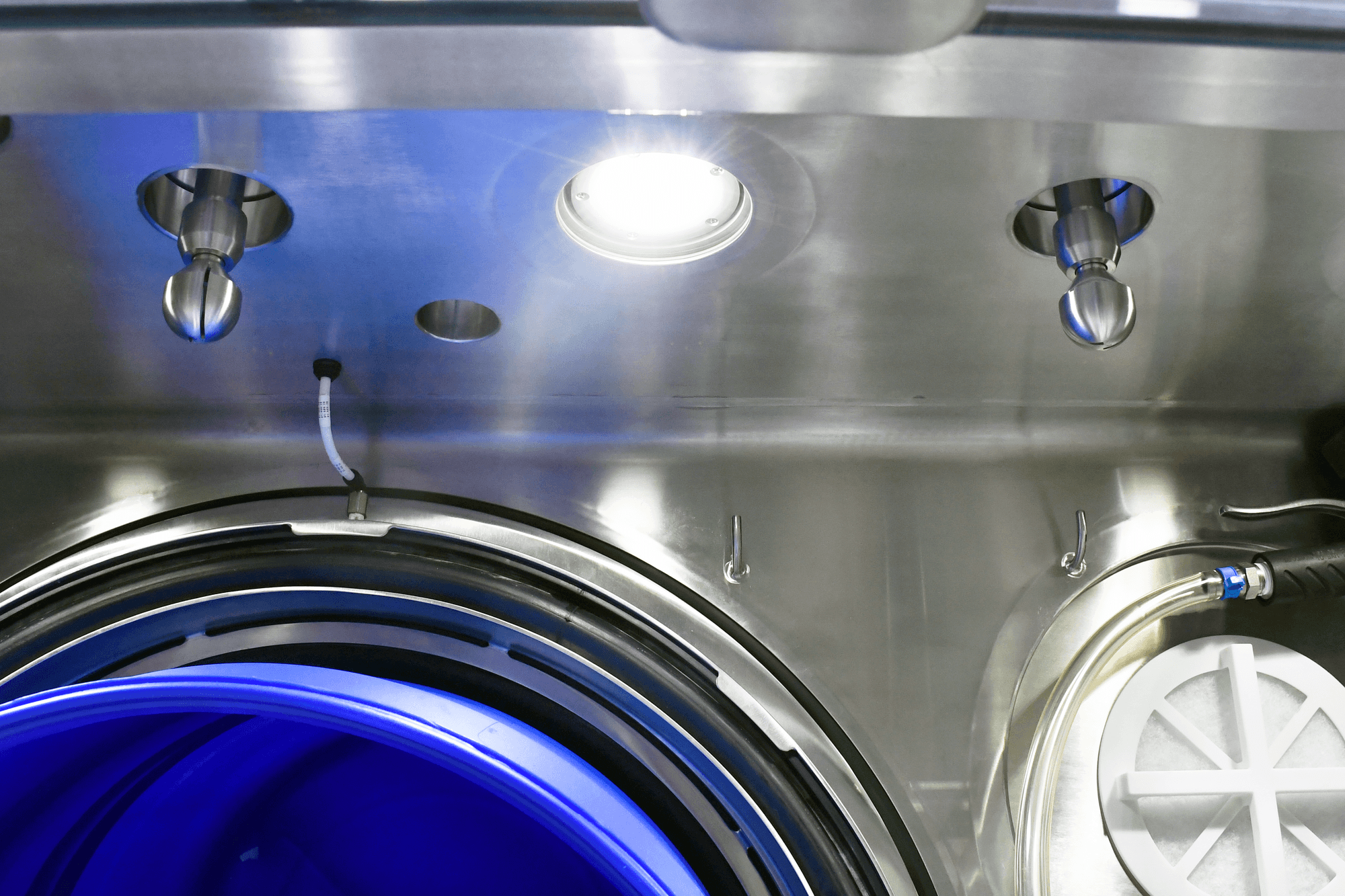

Efficiency: Cleanable chamber design and built-in CIP sequences minimize cleaning time, while efficient material entry/exit methods ensure efficient and ergonomic material handling.

Reliability: Rheo has developed vast process experience in the Containment Isolator product line and offers full validation and testing services to ensure reliable performance.

Rheo hosted a Townhall event on Process Containment. See additional information and request materials here.