The Drum Tipper has several benefits when implemented in the manufacturing process:

|

|

The Drum Tipper has several benefits when implemented in the manufacturing process:

|

|

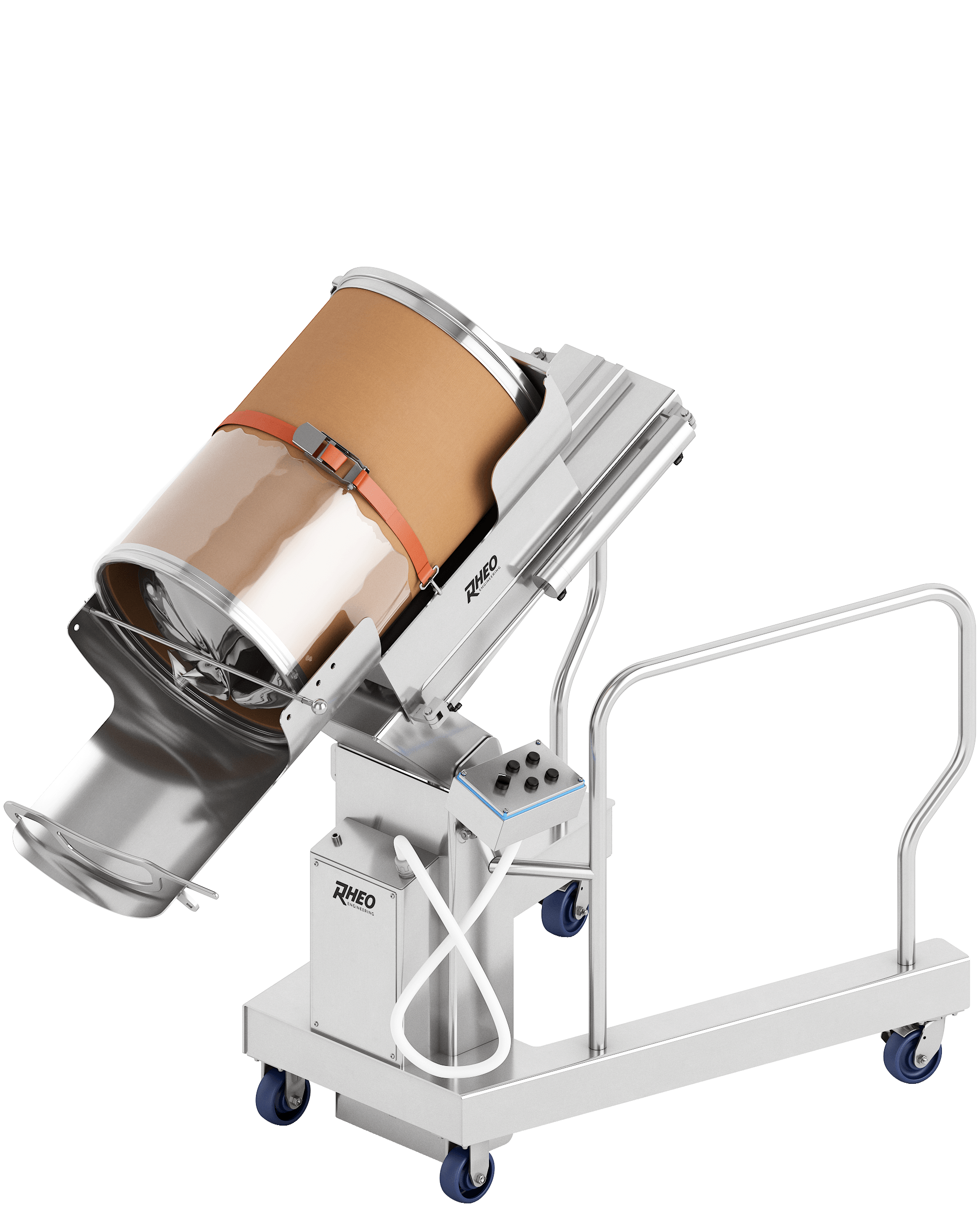

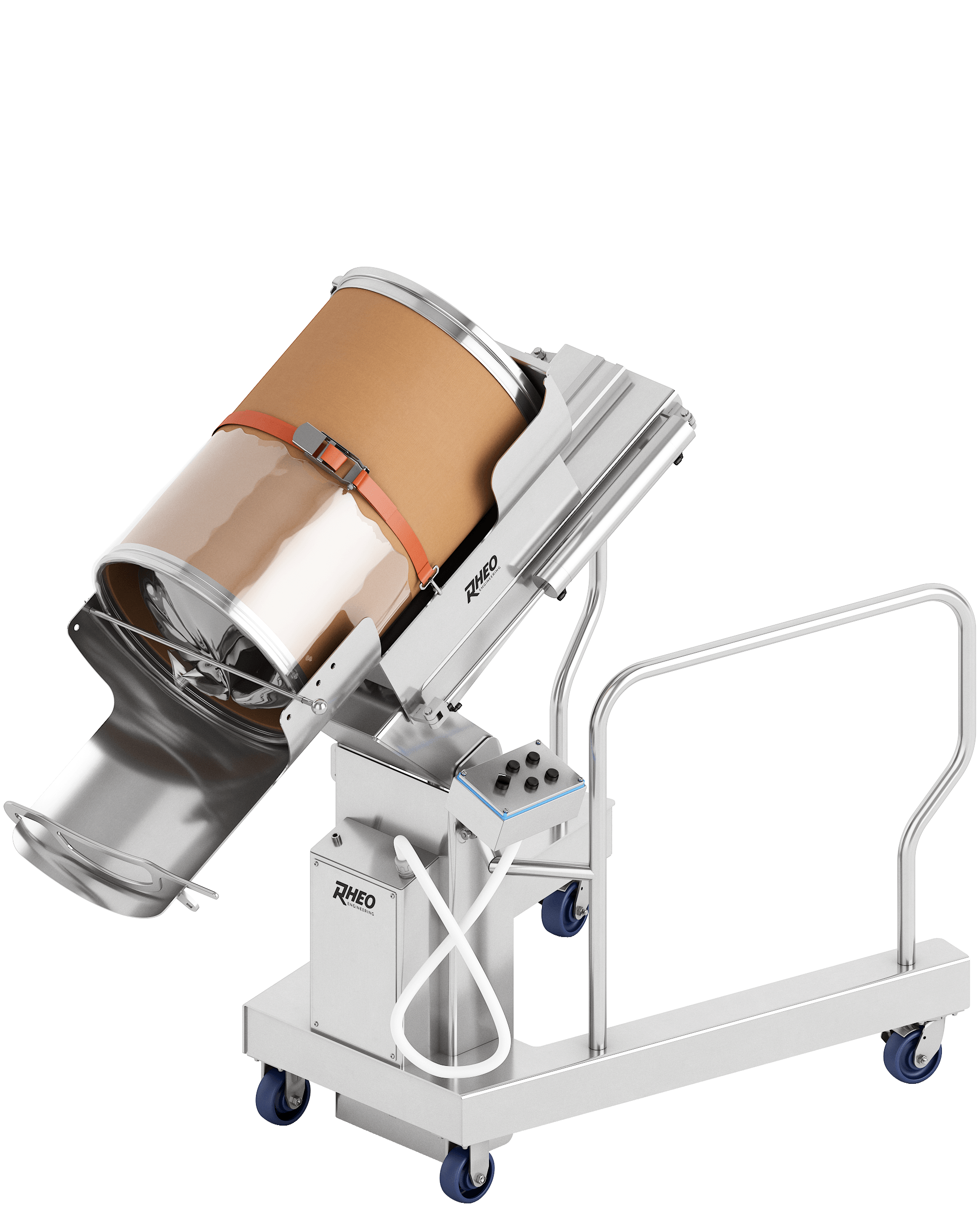

By designing around an analysis of operator movements during the drum charging process, an unmatched level of safety, operating simplicity, and functionality is achieved. A drum can be raised, lowered, and tipped into the proper position by using a single hand or foot control. This approach to drum handling allows the operator to easily control the product flow during the entire charging process.

All exposed surfaces on the Drum Tipper can be fully washed-down for cleaning. Most exposed surfaces are stainless steel, with the exception of some small plumbing components.

Rheo offers several different surface finish options to fit your application needs.

Visit our GMP Compliance page to learn more.