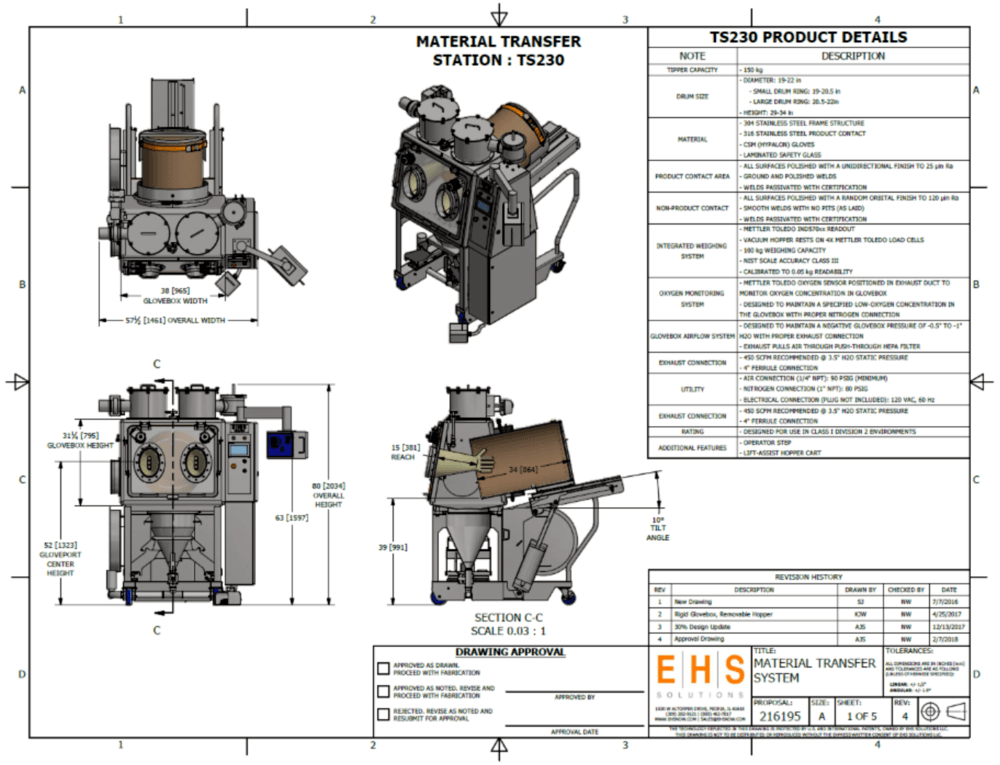

The Rheo Material Transfer Station is a small footprint workstation that improves operator safety and efficiency during the material transfer and weighing process. The operator workstation with the integrated drum tipper provides a compact, GMP, ergonomic means of transferring material.

The Material Transfer Station with Rigid Glovebox Containment is designed for highly contained, closed transfers for highly toxic products and APIs. Containment levels of 1-0.01 µg/m3 can be achieved via the rigid glovebox.

Rheo has conducted performance verification tests on the Material Transfer Station. The tests showed excellent results for each of the different configurations tested. Copies of the executive summary, full reports, and supplemental documentation are available upon request.

The portable Material Transfer Station for Packout offers a fully designed containment system that allows for the filling and weighing of the powder into lined drums.